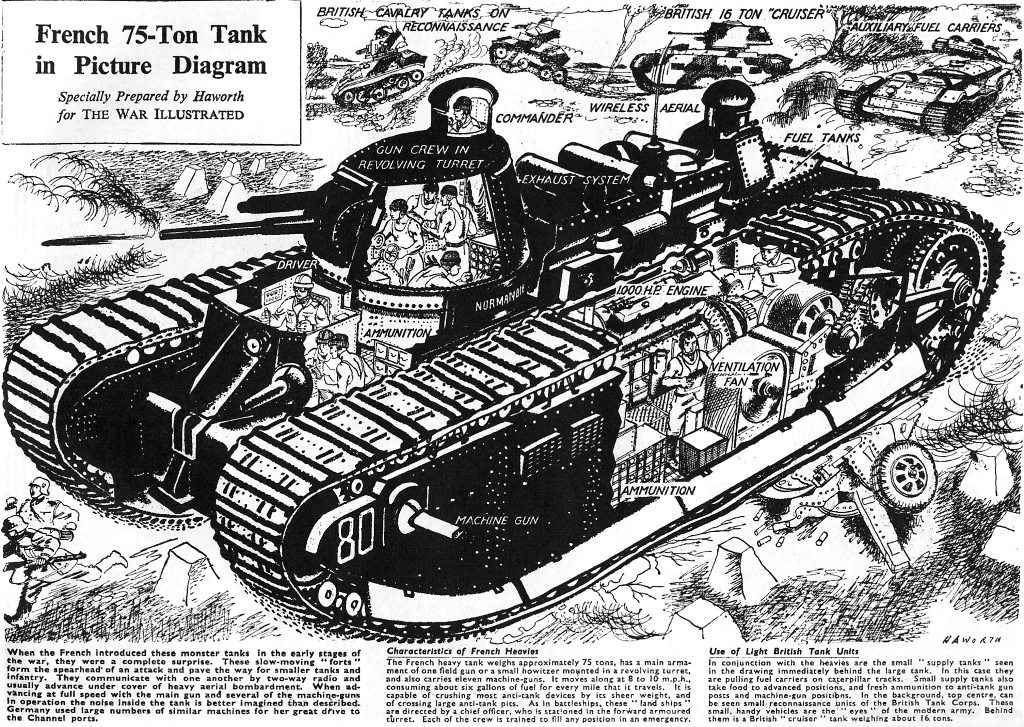

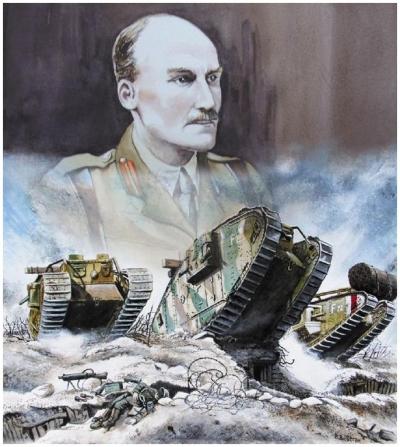

At a time when most soldiers regarded the tank as a specialized infantry-support weapon for crossing trenches, a significant number of officers in the British Army's Royal Tank Corps had gone on to envision a much broader role for mechanized units. In May 1918, Colonel J.F.C. Fuller, the acknowledged father of tank doctrine, had used the example of German infiltration tactics to refine what he called "Plan 1919". This was an elaborate concept for a large-scale armoured offensive by the British Army in 1919.

Colonel J.F.C. Fuller, the acknowledged father of tank doctrine

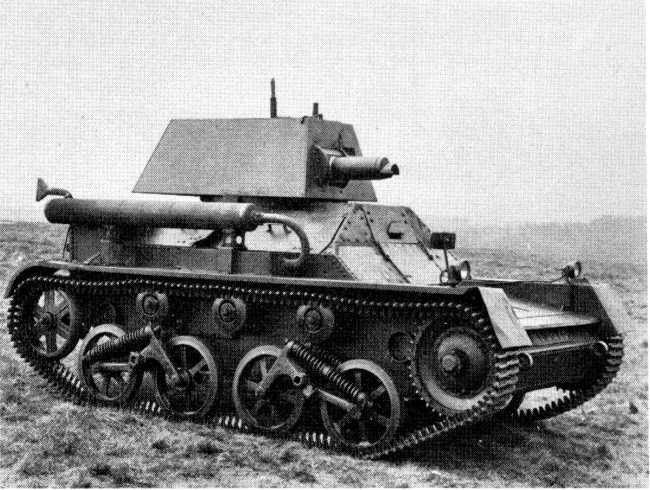

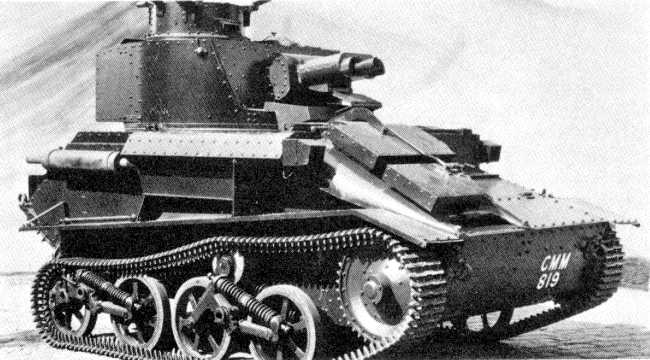

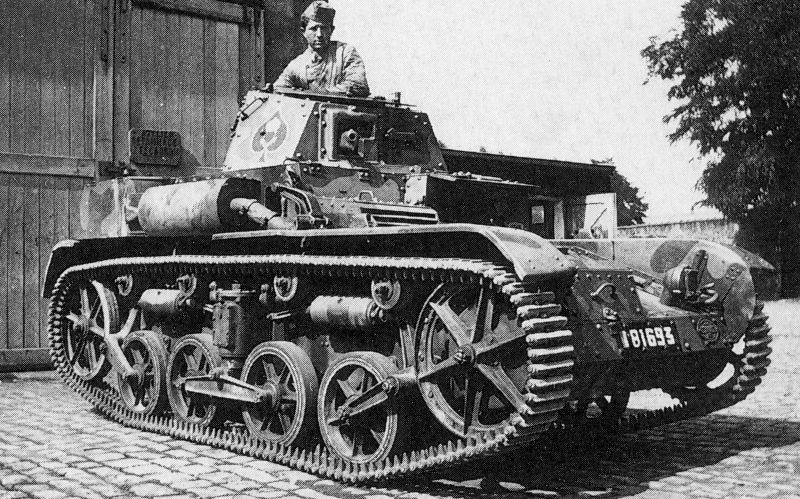

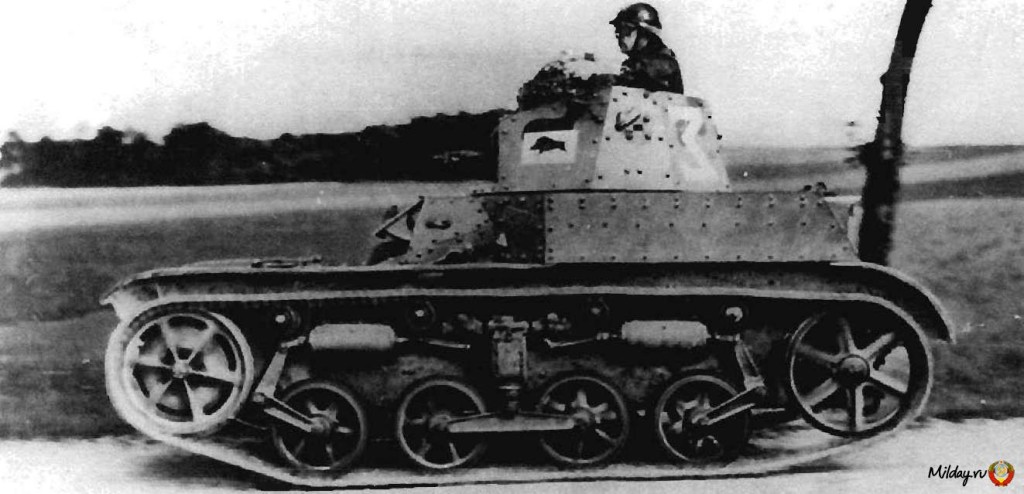

The British Army's interest in tanks post-WWI was for fast, lightly armoured, mobile vehicles - the light and medium (or "cruiser") tanks - tasked with reconnaissance and constabulary-type colonial roles, with cheapness the major design factor. Through the 1920's, this resulted in a line of light tanks being built for the British Army by Vickers-Armstrong, with the first being the Vickers Light Tank Mark I.

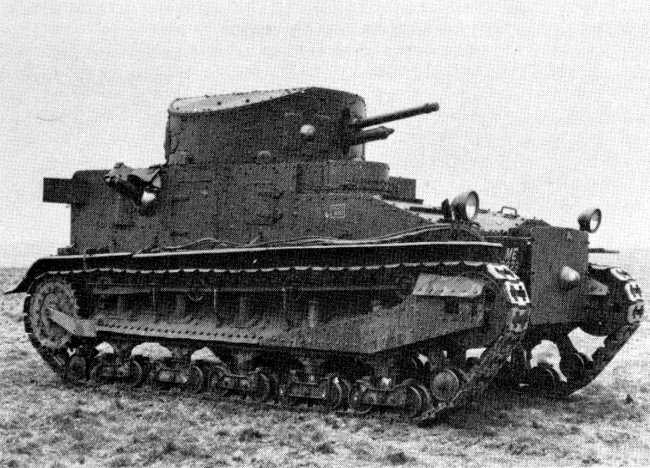

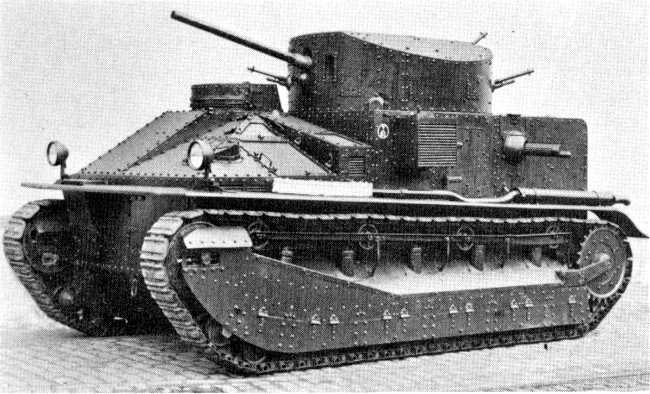

In 1920 the British Army planned to acquire a Light Infantry Tank. Colonel Johnson of the Tank Design Department derived a design such a type from the Medium Mark D. In competition, Vickers built the Vickers Light Tank but the project was abandoned in 1922 in favour of a generally more conventional design: the Vickers Light Tank Mark I, that was renamed the Vickers Medium Tank Mark I in 1924. The first prototypes were sent to Bovington for trial in 1923. The Medium Mark I replaced some of the Mark V heavy tanks; and some 200 served in the Royal Tank Regiments, being phased out only in 1938. The Medium Mark I was the first tank to see "mass" production following WW1 and represented most of the world's tank production during the 1920's.

The Vickers Medium Mark I

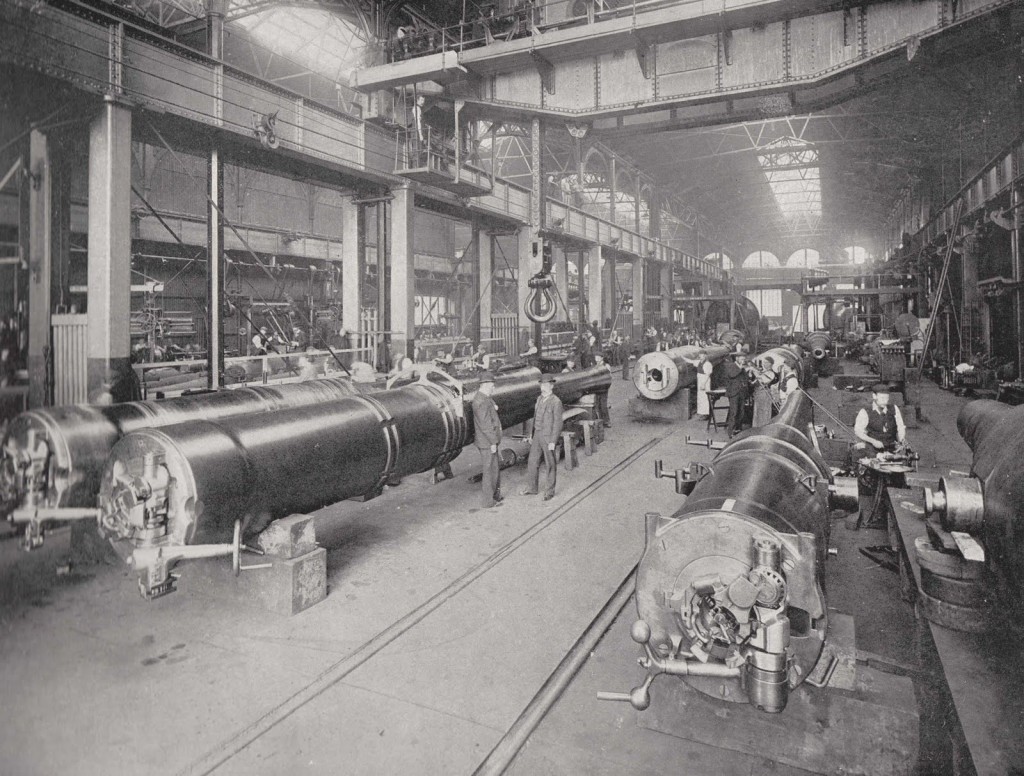

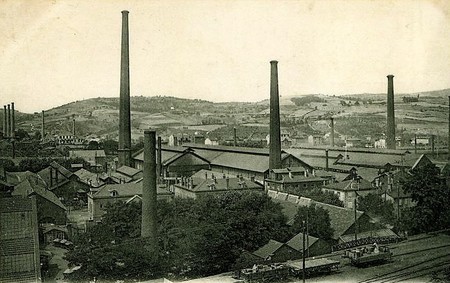

After the First World War, Britain disbanded most of its tank units leaving only five tank battalions equipped with the Mark V and the Medium Mark C. At first a large budget was made available for tank design but this was all spent on the failed development of the Medium Mark D. In 1920 the Infantry had plans to acquire a Light Infantry Tank. Colonel Johnson of the Tank Design Department derived such a type from the Medium Mark D. In competition Vickers built the Vickers Light Tank. Vickers were not conspicuously interested in tanks – they had made none during the Great War and no big orders were expected. Nevertheless, the post-war arms market being somewhat limited, they set up a small staff and determined to see what they could do.

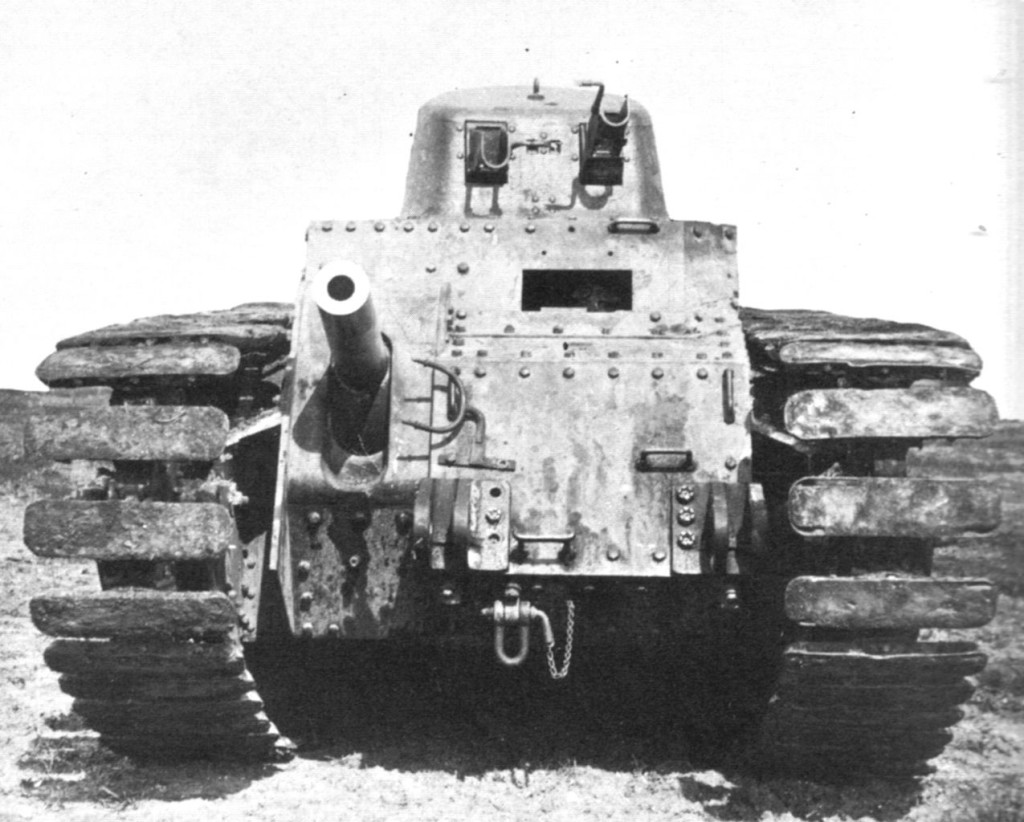

Vickers Medium Mark I A

The design office was set up in Sheffield, where the team produced plans for the tank starting from scratch. Due in large part to the first post-war economic recession, their design reflected a stringent frugality, although the Vickers design was still reminiscent of the Great War types. It had a high, lozenge-shaped, track frame with side doors but it also showed some improvements. There was a fully revolving turret and the suspension was sprung by vertical helical springs, while the Medium Mark C still had a fixed turret and was unsprung. The Vickers Light Tank was much smaller than the Medium C at just seven feet high and weighing only 8.5 short tons. It was driven by a separately compartmented 86 hp engine through an advanced hydraulic Williams-Jenney transmission, allowing infinitely variable turn cycles.

Vickers Medium Mark I

When the government design bureau, the Tank Design Department, was closed in 1923 any direct official involvement in tank development was terminated. However, Vickers-Armstrong company went ahead and built two prototypes in 1921. The first prototype was a "Female" version with three Hotchkiss machine guns; the second prototype was a "Male" which had a 3-pounder gun in place of one of the machine guns and also a machine gun for anti-aircraft use. It looked far closer to a modern tank than its predecessors with the turret, the front of the fighting compartment and the hull front plate all strongly rounded. The advanced transmission proved to be utterly unreliable however and the project was abandoned in 1922 in favour of a generally more conventional design, the Vickers Light Tank Mark I. This would be renamed the Vickers Medium Tank Mark I in 1924. The first prototypes were sent to Bovington for trial in 1923. The Vickers designation was A2E1.

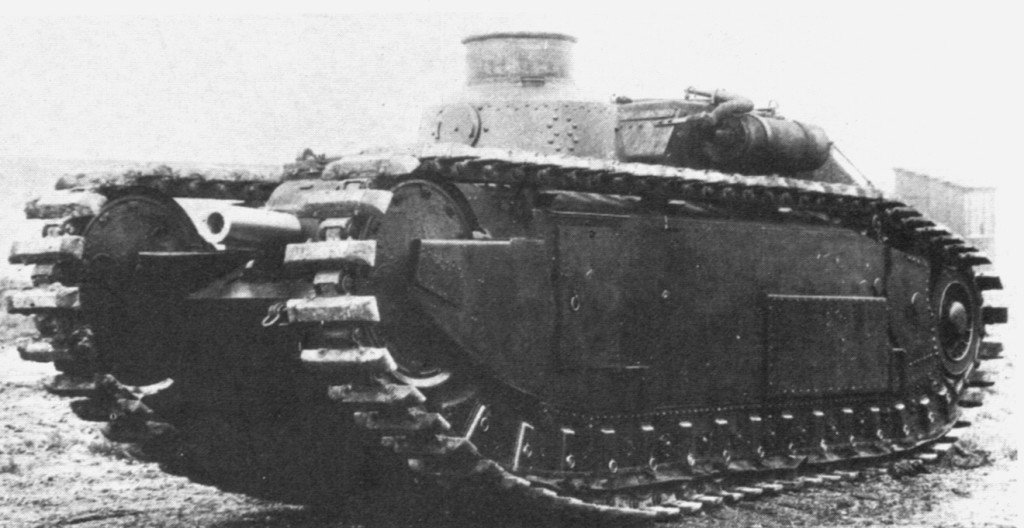

Despite being in general more conventional, in one aspect the Medium Mark I looked rather modern: instead of a high track run it possessed a low and flat suspension system with five bogies, each having a pair of small double wheels. The axles of these were too weakly constructed; as Major-General N.W. Duncan put it in his Medium Marks I-III: "(...) a perpetual nuisance. The axles were continually breaking and the path of the Mark I tanks was littered with discarded wheels". This was cured by switching to a "box bogie" in 1931. To ease repairs the suspension was not protected by an armoured covering. There were two vertical helical springs of unequal length in each of the five bogie casings attached to the hull. In front and behind the normal ten road wheel pairs, there was a tension wheel pair. Ground pressure was very high, even though at 11.7 long tons the vehicle was not very heavy for its size.

The engine was an air-cooled 90 hp Armstrong Siddeley engine derived from an aircraft type. Surprisingly the engine and transmission was distributed throughout the hull - with the engine to the left of the driver, the gearbox underneath the commander and final drive at the rear, which Duncan describes as "an unbelievable retrograde step in view of war-time experience". The Medium Mark B and the Mark VIII had introduced compartmentalisation to reduce the debilitating effects of engine noise and fumes on the crew. However with the Medium Mark I considerations of ease of maintenance took precedence.

Vickers Medium Mark I

The engine drove, via a multiple dry-plate clutch, a four-speed gearbox. It had no synchromesh and switching between gears without excessive noise was a challenge to the driver. A propeller shaft connected the gearbox to a bevel box at the end of the tank which divided the power to a separate epicyclic gear for each track. These gears automatically provided extra emergency torsion to the normal first and second gear if the vehicle suddenly slowed down due to an obstacle or soft ground. The petrol tanks were at the very rear of the hull, so the fuel lines had to run along the whole length of the vehicle, pumping fuel to a secondary tank that fed the engine by gravity. The engine was lubricated and partially cooled by oil; leakage was common and the original four-gallon reservoir had to be replaced by a 13.5 one. The tank could be electrically started, but only if the motor was already warm, so the first start had to be done by hand from the inside of the vehicle. Maximum speed was about 15 mph and the range about 120 miles (although Captain Liddell Hart has written that it could actually travel at nearer to 30mph).

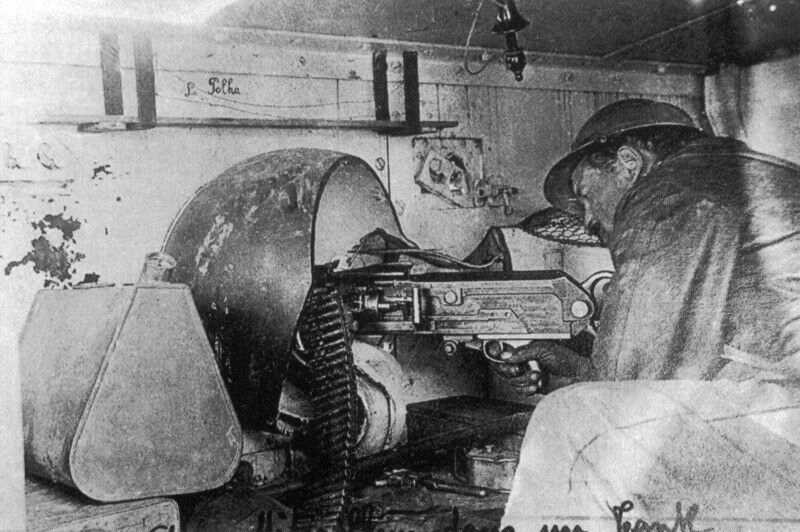

There was a cylindrical bevelled turret on top of the hull that carried a "Quick Firing" (shell and cartridge in one complete round) three-pounder gun (47 mm calibre) and four ball mountings for Hotchkiss machine guns. A novel, unique feature was a three-man turret. This meant that commander was not distracted with performing either the loader's or gunner's tasks and could fully concentrate on maintaining situational awareness. In this respect the design of the Medium Mk I was important since it established a turret layout that encouraged teamwork by improvements in manual efficiency as well as enhancing morale in action. This gave a huge potential combat advantage, but went largely unnoticed at the time. Other manufacturer's tanks did not have this capability until the German Panzer III was developed in 1937.

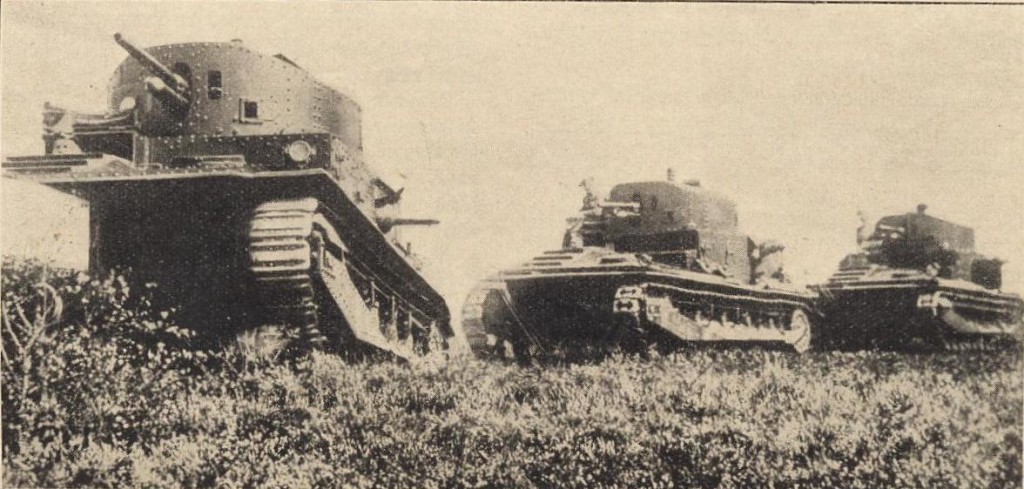

Vickers Medium Mark I tanks on the move in England in the 1930s

The practical importance of this feature is signified by the fact that later in World War II, most of both sides tanks' designs either quickly switched to the three-man turret, or were abandoned as obsolete. There was no co-axial machine gun. There was only room to operate one machine gun from the turret; normally one gun was switched between the respective mountings as the guns were removable. The turret machine gunner doubled as main gun loader. In each side of the hull was a Vickers machine gun. There was one gunner to operate these, he also functioned as the mechanic.

The shape of the Mark I Medium hull was very distinctive. The back was a simple armoured box; the front plate was high and perfectly vertical. Between them, from the armoured hood of the driver at the right of the vehicle six armour plates fanned out to the left, making for a complex hull geometry on that side. All in all the Vickers Medium Mk I tank gave an impression of being ungainly and squat. The crew of five was only poorly protected by 6.25 mm plating, rivetted to the chassis, barely enough to counter the threat posed by light machine guns (and indeed, thinner than the WW1 tanks, some models of which had not been bullet proof to the detriment of their crews). With its many shot traps the vehicle was unable to withstand even anti-tank rifle fire and it had a high profile. The internal lay-out worsened this vulnerability as the petrol tanks were inside the main compartment.

The Medium Mark I was the first tank to see "mass" production since last tanks of the Great War were completed. No foreign orders were placed for the Medium Mark I, although apparently half a dozen went to Australia). It was in fact so well built that few replacements were needed. These British Mediums represented most of the world tank production during the 1920's. They never fired a shot in anger and their performance in a real battle can only be speculated upon but as the only modern tanks in existence in the decade after the First World War they provided the British with a unique opportunity to test the many new ideas about mechanised warfare using real operational units. This opportunity was exercised only grudgingly.

Vickers Medium Mk I and II were outdated by the time the outbreak of ww2 and was used as trainers. A few were used in North Africa.

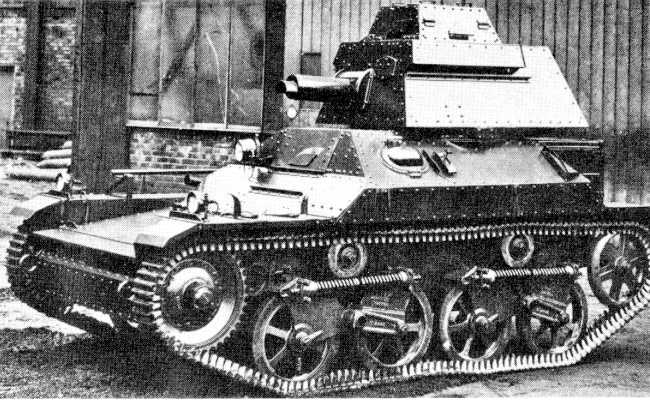

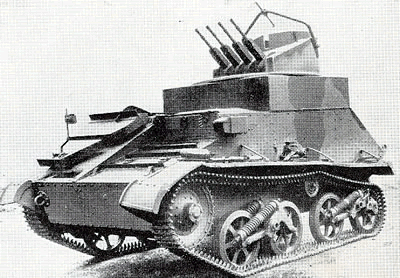

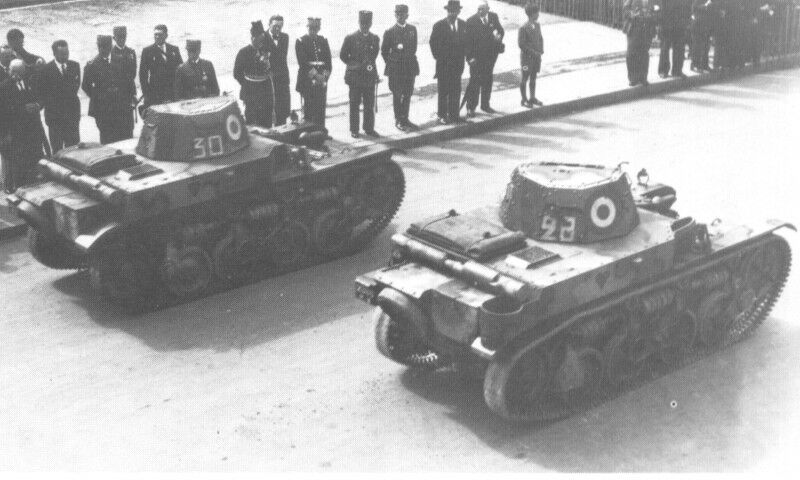

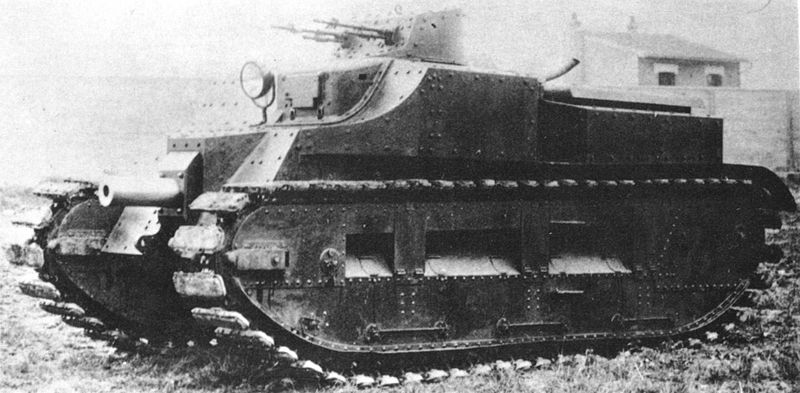

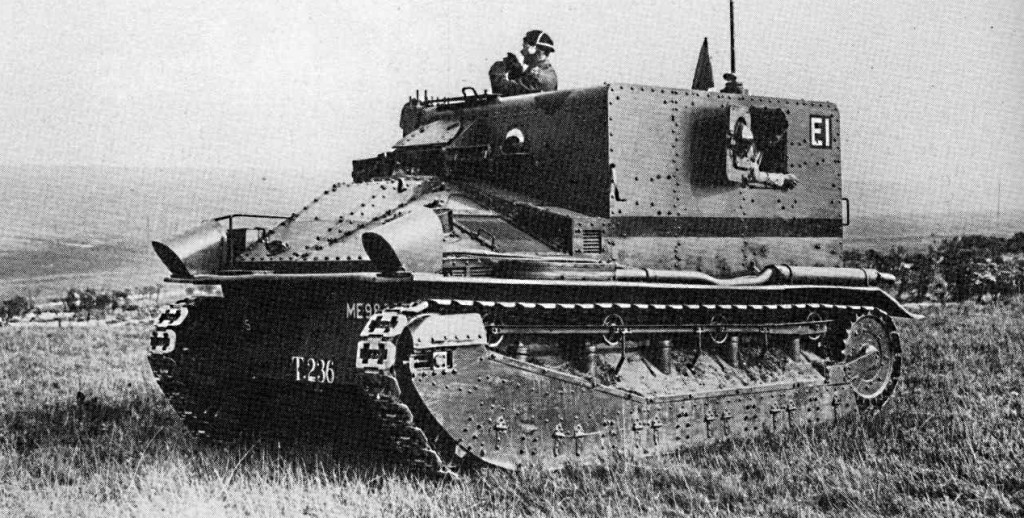

The Vickers Medium Mk II

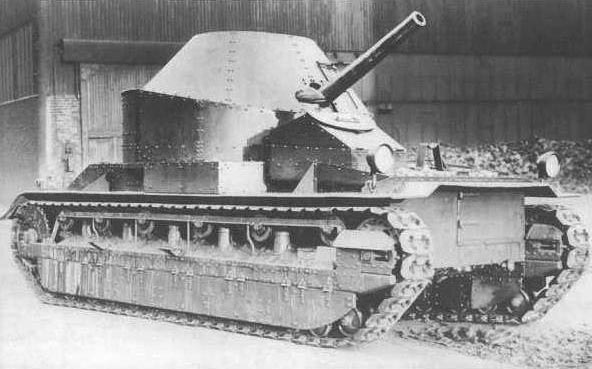

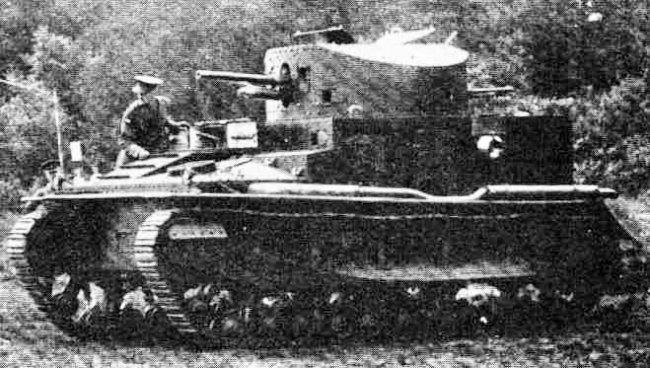

The Medium Mk I's successor, the Vickers Medium Mark II, was derived directly from the Mk I and was intended to replace the last of the WW1-era Medium Mark Cs still in use. Production and rebuilding ran from 1925 until 1934, with the Mk II phased out of service from 1939. The Mark II used the same chassis, suspension and transmission as the Medium Mark I but had a new superstructure. It featured several improvements over the Vickers Mark I, among them a higher superstructure with the driver's vizor on top of it instead of in front of it; an improved suspension protected by armour skirts; and Rackham clutches, providing a primitive form of mechanical servo-control. Due to a slightly higher weight its rated speed was somewhat slower than that of the Medium Mark I, at 13 mph compared to 15 mph.

It had a fully rotating turret on top of the hull, but also mounted a dual-use 3-pounder gun (firing both high-explosive and anti-tank shells) with a coaxial machine gun. Other improvements included thicker armor, better driver vison, and armor skirting that provided protection for the suspension. The back of the turret had a slope so that the machine gun there could be used against aircraft.

Vickers Medium Mk II

The Mk II weighed 12 tons, carried a crew of 5 and was powered by a 90hp Armstrong Siddeley V-8 engine, with a range of 193 kms. Armour varied from 6.25 to 8mm and was riveted, with armoured skirting also providing protection for the suspension. A number of variants were built (the list below is not exhaustive, I've omitted a few irrelevant variants such as tropical tanks, one-of prototypes, etc.). A total of 167 Mk II's were delivered between 1926 and 1929, although mnay were also rebuilt and improved on through the 1930's:

- Mk II – the original version, of which one hundred were built

- Mk II* - Fifty-six of the same vehicles with the Hotchkiss machine guns removed, a coaxial Vickers machine gun added and the commander's post shifted somewhat further back as in the original position he had been in a very real danger of being hit in the stomach by spent shells ejected by the main gun's breech block;

- Mk IIA - Twenty vehicles newly built in 1930

- Mk II** - in 1932 the remaining 44 Mark II's were brought to Mark II* standard; in addition a wireless set was fitted in an armoured container at the back of the turret. the weight rose to 13.5 short tons

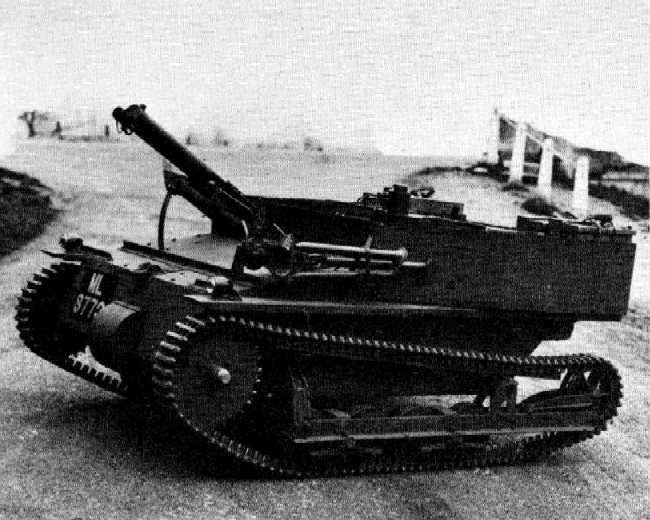

- Mk IIA CS - some Mark IIAs were later rebuilt as close support vehicles, their main armament replaced by a 15-pounder 3.7 inch mortar, mainly intended to give smoke cover, though some HE shells were also carried. Each company headquarters was equipped with two of these vehicles. The weight was increased to 14 tons.

- Mk D - the Vickers Mk. D was a one-off design built for the Irish Free State and delivered in 1929. It had a more powerful, water cooled, rear mounted, 6-cylinder Sunbeam Amazon petrol engine, developing 170 bhp at 2100 rpm. A 6 pdr gun was fitted and as many as 4 Vickers .303 machine guns. The tank was scrapped in 1940.

- Mk II Box Tank - This was a single command tank, converted from a Medium II in 1928, by removing the turret from the fighting compartment and fitting a large rectangular superstructure. Its only armament was a single machine gun in a ball mounting in the front of that armoured box. Two radio sets were fitted: a short range set for tactical communication and a long range one to contact higher levels. The Box tank was first used by a battalion commander and from 1931 by the Brigade Commander.

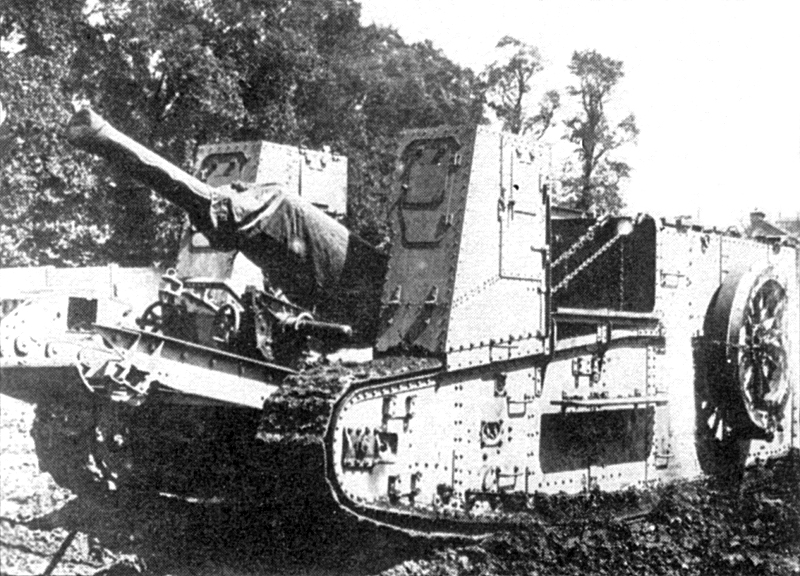

- Birch Gun: three prototypes built between 1926 and 1929 of a self-propelled gun for the experiments then conducted in the field of mechanised warfare. The Mark I had the Ordnance QF 18 pounder, The Mark II chassis was lengthened and fitted with an 75 mm gun on a mounting capable of high elevations.

Vickers Medium Mk II Box Tank

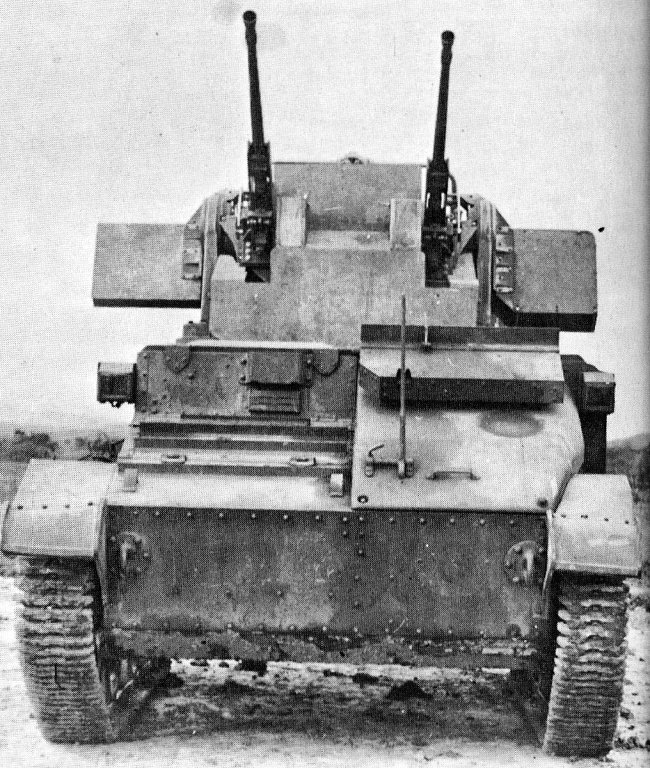

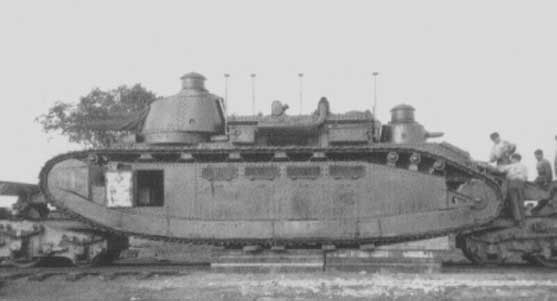

The Vickers Independent A1E1 was a multi-turreted tank designed by the British armaments manufacturer Vickers in the early 1920's. Although it only ever reached the prototype stage it would influence many other tank designs and is thus worthy of mention. The tank was the subject of industrial and political espionage, the plans ending up in the Soviet Union, where they may have influenced the design of the T-28 and T-35 tanks (the T-35 in particular was based extremely closely on its plans and layout). Norman Baillie-Stewart, a British military officer, was court-martialled in 1933 and served five years in prison for providing the plans of the Independent (among other secrets) to a German contact. The A1E1 design can be seen as a possible influence on the Soviet T-100 and T-28 tanks, the German Neubaufahrzeug tanks, and the British Medium Mk III and Cruiser Mk I (triple turret) tank designs.

Independent Heavy Tank A1E1

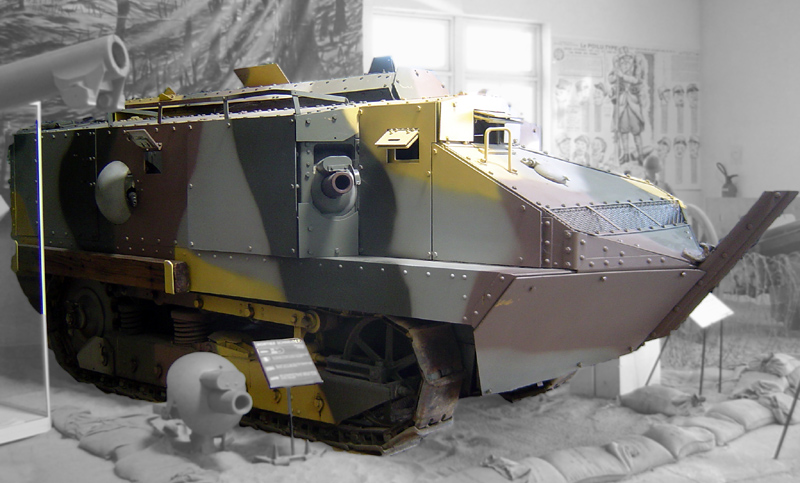

In 1924 the General Staff of the British Army ordered the prototype of a heavy tank, which became known as the Independent. The Design Team was headed by Sir George Buckham, who had been with Vickers since 1895, with much of the design completed by Walter Gordon Wilson along with three relatively junior Tank Corps officers, Major Darwell and Captains Busk and Bloomer, from whom most of the ideas came. Its 35.8 litre V12 350hp air-cooled engine was designed by Armstrong Siddeley, and it also incorporated a new hydraulic braking system which had to be specially developed due to its weight and speed. The prototype was delivered to the War Office in 1926, but was abandoned due to a lack of funds.

The Independent was a multi-turret design, having a central gun turret armed with a 3 pounder (47 mm) gun, and four subsidiary turrets each armed with a 0.303 inch Vickers machine gun. The subsidiary turrets were mounted two at the front and two to the rear of the turret (about halfway along the hull). The gun of the left rear turret was able to elevate to engage aircraft. The tank was designed to have heavy firepower, self-defence capability, and superiority to enemy weapons. It had a crew of eight men, the commander communicating with the crew through an intercom system.

The Independent was the first tank worthy of being called a battle tank but was never used in combat. The drawback of course was the cost. For anyone interested, the Vickers A1E1 Independent is preserved at the Bovington Tank Museum in the UK, a mute witness to the spinelessness of Britain's inter-war politicians.

The story of ex-Gordon Highlander Norman Baillie-Stewart

(the below with all credit to phylo_roadking from www2talk.com and forum.axishistory for his posts on this gentleman)

Norman Baillie-Stewart (15 January 1909 – 7 June 1966) was a British army officer who became known as “The Officer in the Tower” when he was imprisoned in the Tower of London. Baillie-Stewart was born to a military family named Wright and was given the forenames Norman Baillie Stewart. He attended Bedford School and the Royal Military College, Sandhurst, where, as a cadet, he served as an orderly to Prince Henry, a younger son of King George V. In January 1929, while still a cadet, he changed his surname from Wright to “Baillie-Stewart”, perhaps under the belief that he was looked down upon by more senior officers, even though his father had been a colonel and his mother was from a family with a long tradition of military service. He graduated tenth in the order of merit and in February 1929 received a commission as a subaltern in the Seaforth Highlanders, although apparantly he he soon grew to dislike army life.

Norman Baillie-Stewart

On a holiday in South Africa, Baillie-Stewart met a German woman with whom he fell in love. He decided to become a German citizen and wrote a letter to the German Consul in London offering his services. On holiday in Germany in 1931, he sold military secrets for sexual favours and relatively small amounts of money. His regular trips to the Netherlands to meet his handlers attracted suspicion and he was arrested in 1933. In the spring of 1933, Baillie-Stewart was court-martialed at Chelsea Barracks under the Official Secrets Act for selling military secrets to a foreign power. Amongst the military secrets that he sold to the Germans were the plans and photos of the A1E1 tank.

In a two-and-a-half-hour speech, the Prosecutor, Major Harold Shapcott, outlined the Government’s case. The court was told that Baillie-Stewart’s offending had begun in 1931 when he met and fell in love with a German woman while holidaying in Germany, and decided to become a German citizen, writing a letter to the German Consul in London offering his services. Receiving no answer, he traveled to Berlin without permission to take leave, where he telephoned the German Foreign Ministry and demanded to talk to an English speaker. This resulted in him making contact with a Major Mueller under the Brandenburg Gate, where he agreed to spy for Germany.

On the plea that he was studying for Staff College examinations, he had borrowed from the Aldershot Military Library the specifications and photographs of an experimental tank, the Vickers A1E1 Independent, and a new automatic rifle for the infantry, as well as notes on the organization of tank and armored car units. Without special permission he had visited Berlin on leave. It was charged that he sold his secrets to a mysterious German known as “Otto Waldemar Obst”. Major Shapcott pointed out that Obst sounds like Oberst which means Colonel. (That Obst means “fruit” was not brought forward). For these secrets it was charged that Baillie-Stewart received two letters signed “Marie Louise,” one containing ten £5 notes, the other four £10 notes. Evidence was also produced that he had also made several trips to the Netherlands to meet with his handlers. (MI5′s files have since shown that Marie-Luise had been merely a figment of his controller’s imagination; Major Mueller’s covername was Obst (fruit) and Baillie-Stewart’s was Poiret (little pear), while Marie-Luise, a type of pear, was used to conceal their correspondence).

Because Britain is not at war Lieut. Baillie-Stewart’s life was not at stake, but there were ten charges against him. with a maximum penalty of 140 years in jail. He was imprisoned for five years, which he served at the Tower of London, the last British subject to be imprisoned there. While imprisoned, Baillie-Stewart was displayed daily for the public. After his release from prison in 1937, Baillie-Stewart moved to Vienna, where he applied for Austrian citizenship. However, this was refused since he did not meet the residency qualification. In August 1937, the Austrian government suspected him of being a Nazi agent and gave him 3 weeks to leave Austria. Baillie-Stewart’s disenchantment with Britain was increased when the British Embassy in Vienna refused to help him. Rather than return to Britain he moved to Bratislava, which was then in Czechoslovakia.

Following the Anschluss of 1938, Baillie-Stewart was able to return to Austria, where he made a small living from operating a trading company. He applied for naturalisation but the application was delayed by bureaucracy at the Ministry and he did not become a German citizen until 1940. In July 1939, Baillie-Stewart attended a friend’s party where he happened to hear some German English-language propaganda broadcasts. He criticised the broadcasts, and was overheard by a guest at the party who happened to work at the Austrian radio station. He informed his superiors of Baillie-Stewart’s comments, and after a successful voice test in Berlin, Baillie-Stewart was ordered by the German Propaganda Ministry to report to the Reichsrundfunk in Berlin, where he became a propaganda broadcaster. Baillie-Stewart made his first broadcast on the “Germany Calling” English language service a week before the United Kingdom declared war on Germany, reading Nazi-biased “news”.

It has been speculated that it was Baillie-Stewart who made the broadcast which led the pseudonymous Daily Express radio critic Jonah Barrington to coin the term “Lord Haw-Haw”. The nickname possibly referenced Baillie-Stewart’s exaggeratedly aristocratic way of speaking, though Wolf Mittler, another English-speaking announcer, is sometimes considered a more likely candidate. When William Joyce later became the most prominent Nazi propaganda broadcaster, Barrington appended the title and named Joyce “Lord Haw-Haw”, since the true identity of the broadcaster was unknown at the time. Another nickname which was possibly applied to Baillie-Stewart was “Sinister Sam”. By the end of September 1939 it was clear to the radio authorities that Joyce, originally Baillie-Stewart’s backup man, was more effective. Baillie-Stewart, who had gradually became disenchanted with the material that he had to broadcast, was dismissed in December 1939 shortly after his last radio broadcast. He continued to work in Berlin as a translator for the German Foreign Ministry, and lectured in English at Berlin University. In early 1940, he acquired German citizenship. In early 1942, Baillie-Stewart made a brief return to radio under the alias of “Lancer”, making several broadcasts for both the Reichsrundfunk and Radio Luxembourg. He spent much time avoiding the more blatant propaganda material he was asked to present.

In 1944, Baillie-Stewart had himself sent to Vienna for medical treatment, where he was arrested in 1945 in Altaussee, while wearing “chamois leather shorts, embroidered braces and a forester’s jacket” and was sent to Britain to face charges of high treason. Baillie-Stewart only avoided execution because the Attorney-General, Hartley Shawcross, did not think he could successfully try him on charges of high treason, committed by taking German citizenship, and instead decided to try him on the lesser charge of “committing an act likely to assist the enemy”. MI5 reportedly lobbied for him to be sent to the Soviet occupation zone of Germany, where there would be no “namby-pamby legal hair-splitting”. Baillie-Stewart pleaded guilty to the charge and was sentenced to five years’ imprisonment, following which he moved to Ireland under the pseudonym of James Scott, married, and had two children before dying on a Dublin street of a heart attack in 1966.

However, the most memorable end result of his short-lived career as a spy were the German and Soviet derivatives of the one and only Vickers A1E1 Independent Tank. During the 1920s and 1930s, a number of countries experimented with very large, multi-turreted tanks. The British built a single example of the Vickers A1E1 Independent in 1926. The technical details of the Vickers A1E1 Independent were then available to the Germans. No doubt the Russians also acquired a copy of the design. Development of the Neubaufahrzeug (German for “new construction vehicle”) started in 1933 when the then Reichswehr gave a contract for the development of a Großtraktor(“heavy tractor”) to both Rheinmetall and Krupp. Großtraktor was a codename for the development of a heavy tank, Germany being still forbidden to develop tanks under the terms of the Treaty of Versailles.

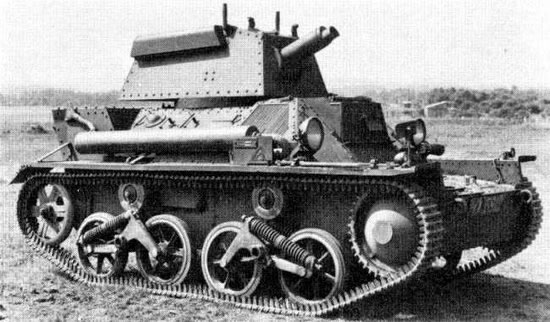

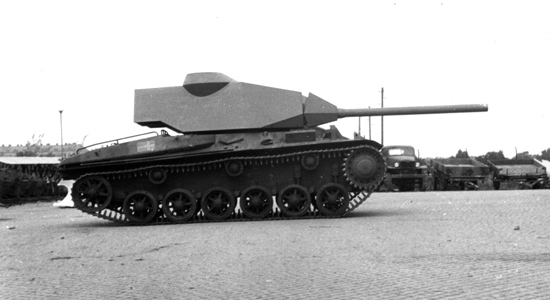

The German Neubaufahrzeug Tank

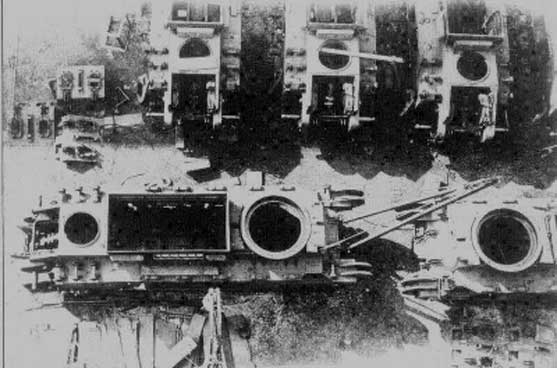

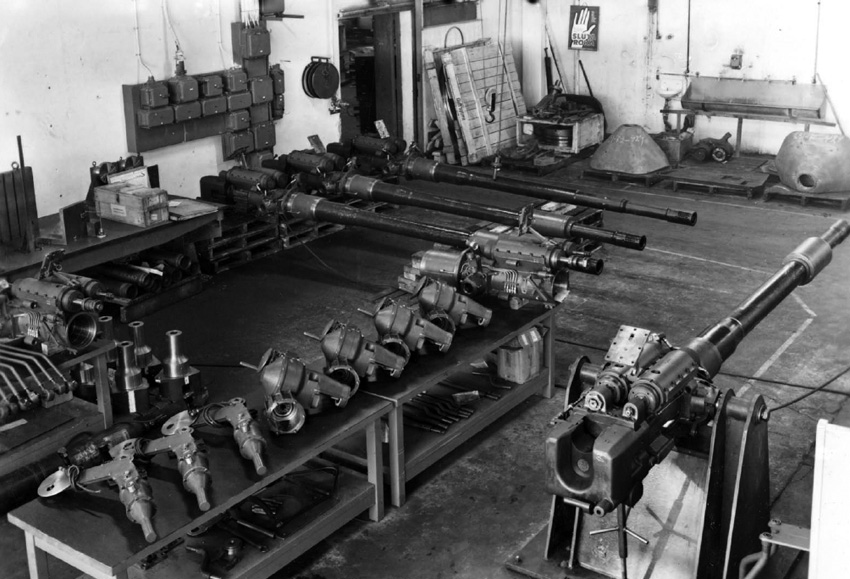

The Rheinmetall and Krupp designs resembled each other to a great extent, the main difference being the weapons placement. Each had a main turret armed with a 75 mm KwK L/24 main gun and secondary 37 mm KwK L/45. Rheinmetall’s design mounted the second gun above the 75 mm KwK L/24, while the Krupp design had it mounted next to the 75 mm KwK L/24. Both designs had a secondary turret mounted to the front and the rear of the main turret. These turrets were slightly adapted Panzer I turrets, with the standard machine gun armament. Rheinmetall’s design was designated PzKpfw NbFz V (PanzerKampfwagen NeubauFahrzeug V), and the Krupp design PzKpfw NbFz VI. It was intended that these designs would fulfill the role of heavy tank in the armored forces, but the design proved to be too complex and unreliable for this role. Nevertheless, development continued in order for the nascent German military to gain experience with multi-turreted tanks. In 1934 Rheinmetall built two mild steel prototypes, both with their own turret design. Three more prototypes were built with proper armor and the Krupp turret in 1935 and 1936.

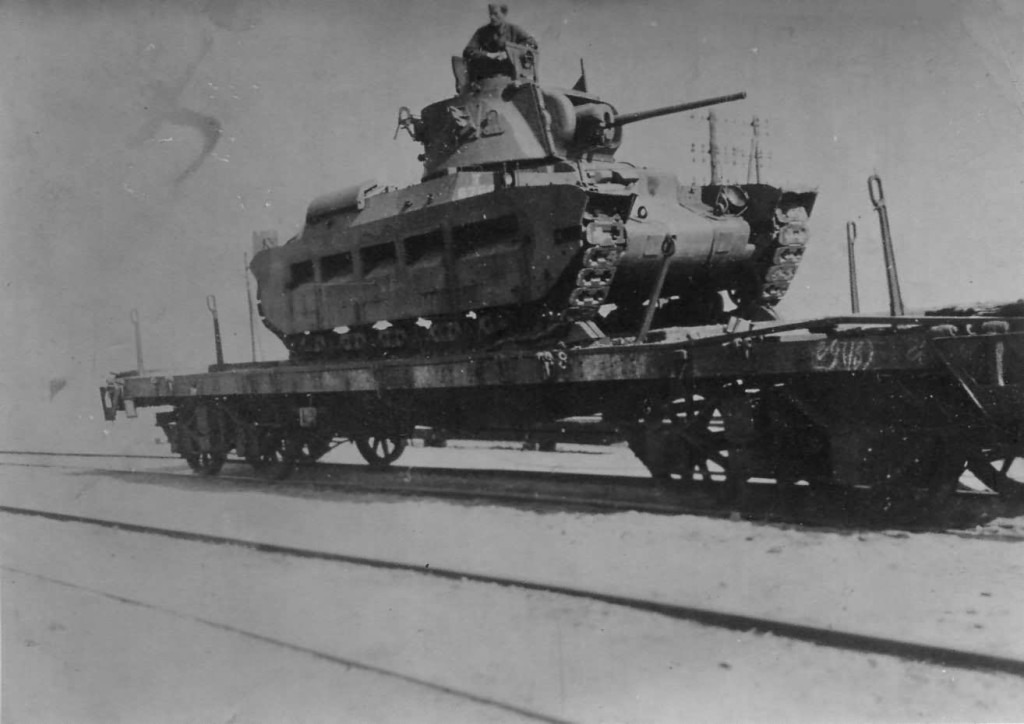

Neubaufahrzeug while being repaired

Though these tanks were never placed in production, they provided a propaganda tool for Nazi Germany, for example being shown at the International Automobile Exposition in Berlin in 1939. This propaganda role was extended with the German invasion of Norway, when a special Panzerabteilung was formed which took the three armored prototypes with them to Oslo. They saw some combat there, with one being blown up by German engineers when it got stuck in swamps near Åndalsnes. To replace it, one of the mild steel prototypes was used. It is unclear what happened to the tanks after the Norway campaign, but none of them survived the war. The surviving vehicles were ordered scrapped in 1941, which took place in 1942 according to documents captured by the British in 1945. The dates upon which the vehicles were scrapped are unclear, but it is thought that the beginning of the construction of the Sturer Emil prototypes dates from the same time. All that survives of these tanks is a small number of running gear parts, preserved in the Gudbrandsdal Krigsminnesamling (Gudbrandsdal War Memorial collection), at Kvam in Norway.

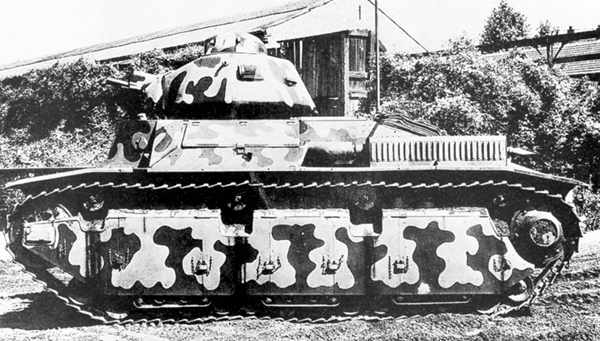

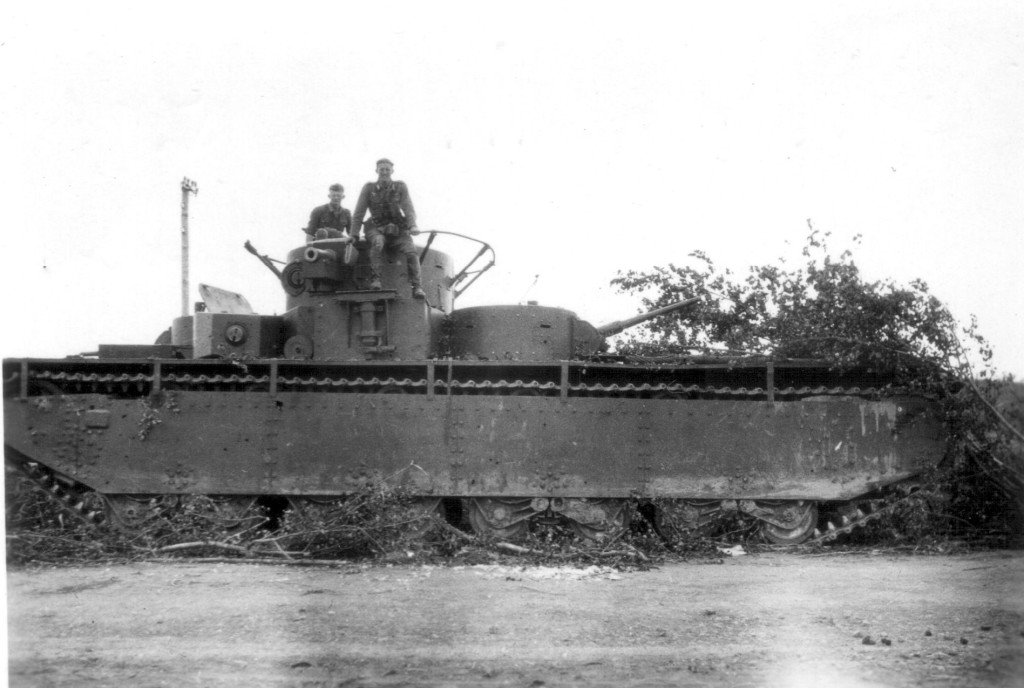

Similarly, the Soviet Union built rather more of the T-35, another clone of the Vickers A1E1 Independent (some 61 T35′s were built). Work began on the T-35 design in 1930 at the OKMO Design Bureau of the Bolshevik Factory, with a design team headed by N. Tsiets. By July 1932, a prototype of a 35 ton tank with a 76.2 mm tank gun was completed. The first prototype was further enhanced with four smaller turrets, two with 37 mm guns and two with machine guns. This first prototype had severe defects in its transmission and was considered too complex and expensive for mass production. Therefore work on it was stopped and a new simpler prototype was built. This new prototype received a new engine, new gearbox and improved transmission. The decision was also made to standardise the turrets used on the T-35 with those employed on the T-28, a triple-turreted medium tank. The small machine-gun turrets were identical on the two tanks. The large main turret housing the 76.2 mm gun was nearly identical, but those used on the T-28 had an additional, rear-firing machine gun. On 11 August 1933, the T-35 was accepted for production. Engineering was shifted to the Kharkov Locomotive Factory, and two batches of ten vehicles were completed.

Soviet T35 Tank

The experiences gained with the two prototypes were used for the main production T-35 Model 1935, which was again improved from the second prototype, with a longer chassis, improved hull and 45-mm guns in place of the 37s. It started production in 1935, and about 35 were built by 1938. In general, throughout its production run small improvements were made to the individual tanks. Production tanks had turrets similar to the ones on the BT-5, but without the rear overhang. Some examples had flamethrowers instead of one of the 45 mm guns. The final batch was a run of six T-35 Model 1938′s, which had new turrets with sloped armour all around, as well as modified side skirts and new idler wheels.

Western and Russian historians disagree about the inspiration for the T-35′s design. The former argue it was inspired by the British Vickers A1E1 Independent tank, but this is rejected by many Russian specialists. It is impossible to know the truth, but there is strong evidence to support Western claims, not least failed Soviet attempts to purchase the A1E1. At the same time, the influence of German engineers, who in the late 1920s were developing similar designs at their Kama base in the Soviet Union, cannot be discounted. What is clear is that borrowing military technology and ideas from other nations was common to the majority of the armed forces in the inter-war years. The Red Army, with its purchase of the British Vickers Carden Loyd tankette, Vickers E-Light and Cruiser Mk II Medium tanks, and of the American Christie suspension for production use in its own vehicles, was clearly one of the leading exponents of this practice. Due to its high cost, the production run of the T-35 ended at just sixty-one tanks.

Knocked out Soviet T-35 tank

During Operation Barbarossa, ninety percent of the T-35′s lost by the 67th and 68th Tank Regiments were lost not to enemy action but through either mechanical failure or because they were abandoned and destroyed by their crews. The most common causes of breakdown were transmission-related. The last recorded action of the T-35 took place during the early stages of the Battle of Moscow. At least one captured T-35 was shipped to Germany for evaluation at the Kummersdorf military proving ground. The T-35 is sometimes cited as having participated in the Winter War against Finland, but according to Soviet sources it did not. In fact, two other prototypes of multi-turreted heavy tanks had been sent to the front for testing:T-100 and SMK. The SMK tank was disabled by a Finnish land mine and all attempts to recover the 55-ton behemoth failed. Finnish photographs of the previously unknown tank were mistakenly designated T-35C by German intelligence. Four T-35 machines were used in training facilities in the Soviet rear. One of these still exists in running condition and is accessible to visitors at the Kubinka Tank Museum near Moscow.

German troops posing on a captured T-35

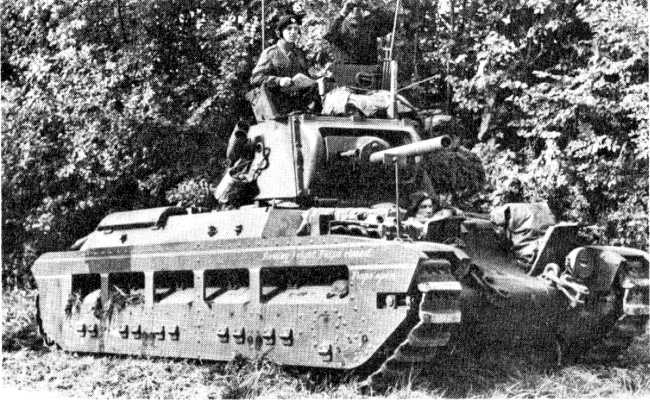

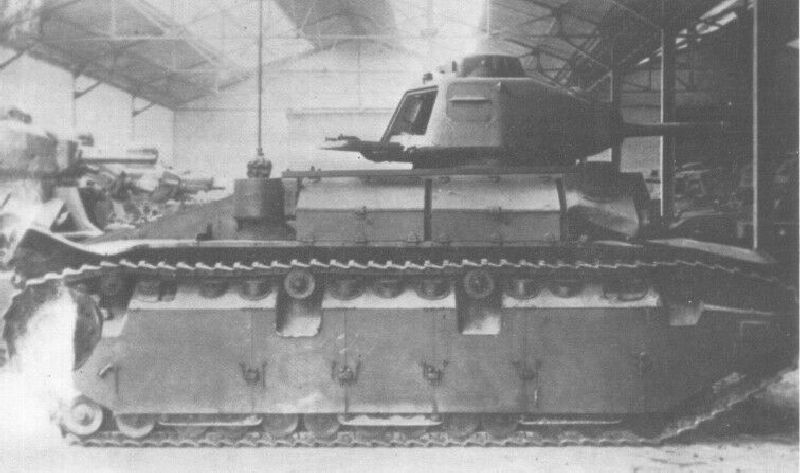

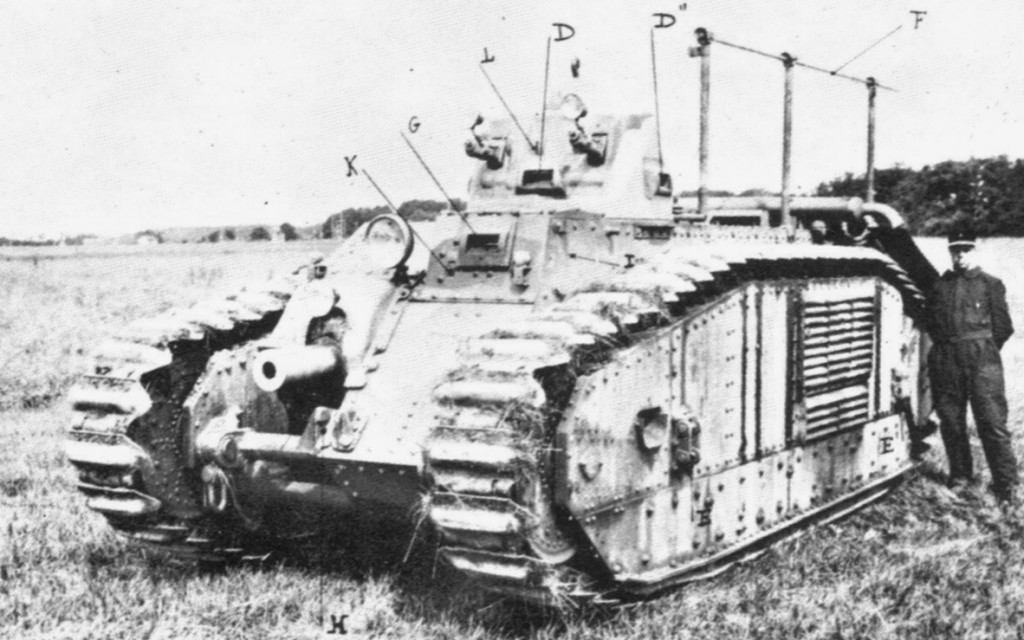

The Vickers Medium Mk III (A7)

The Medium Mark III was unsuccessful with only 3 built. The design did not directly derive from earlier Medium Mark II tank but did apply some improvements. The Medium Mk III had its origins in 1926, with the British War Office interested in replacing their existing Mark II tanks with a new design. In May 1926 the Royal Tank Corps Centre was asked for its opinion, which it submitted in July. One of the requirements was a weight limit of 15.5 tons, which led to the nickname "16-tonners". Other specifications included that it could transported by rail; a sufficient supply of lubrication oil to match the range of the tank (dictated by the fuel carried); a wireless set; a gun capable of defeating enemy armour at a range of at least a thousand yards; fuel tanks external to the main compartments and bottom armour sufficient to withstand heavy machine-gun fire when exposed while climbing a crest. Furthermore the machine should be as silent as possible, as with previous types the engine noise tended to incapacitate the crew. The War Office added some extra requirements: a separate engine compartment; superior steering capacity and 13 millimetres frontal armour with 9 millimetres thickness for the other plates.

A Medium Mk III in use as a command vehicle

In September 1926, Vickers, after being given the order to build a prototype, proposed a first design based on the Vickers A1E1 Independent, with the fighting compartment in front and the engine compartment at the back. There would be a central two-man turret with a 3-pounder (47 mm) gun and a coaxial machine-gun; it was intended to house the commander and a special observer, each being provided a separate cupola. In the front of the hull were to be placed two secondary machine-gun turrets, each with a twin Vickers machine gun. At the back of the vehicle, behind the main turret a third machine-gun turret was intended, armed with an anti-aircraft (AA) weapon. A crew of seven men was proposed. Maximum armour would be 13 millimetres and basic armour 6.5 millimetres, limiting the weight to fourteen tons. Riveted plates were to be used. The total fuel supply would be 120 imp gal (550 l) gallons: ten in a small tank inside, gravity feeding the engine; the remainder in external tanks on the fenders. Two engine options were provided: a 120 hp engine that would allow for a speed of 14 mph and a 180 hp engine that would raise this to 20 mph (32 km/h). The design was called the A6.

Vickers Medium Mk III in the factory

In March 1927 a wooden mock-up was presented and after approval, two prototypes were ordered, with the prototypes to incorporate the new hydraulically operated Wilson epicyclic steering gearbox, the predecessor of the Merrit-Brown gearbox. By June 1928 both prototypes (A6E1 and A6E2) were presented to the Mechanized Warfare Experimental Establishment for trials. Vickers was on this occasion ordered to add armour skirts but keep within the weight limit even if it meant removing armour elsewhere. Meanwhile a third prototype had been ordered: A6E3. A6E1, A6E2 and A6E3 were fitted with an Armstrong Siddeley air-cooled V8 180 hp engine giving a maximum speed of 26 mph. A6E2 was later fitted with the Ricardo CI 180 hp engine but this was not satisfactory and the Armstrong-Siddeley was refitted. A6E3 was later re-engined with the Thornycroft 6V 500 hp - a slow running marine engine. It was proposed to combine two Rolls-Royce Phantom engines with the Wilson transmission system on the A6E1, but in view of the costs this was rejected. A6E2 was eventually refitted with the AS V8 180 hp.

The guns were tested in July 1928. This proved that the twin-machine gun arrangement was unworkable; so the A6E3, then being constructed, was fitted with a simplified design with a single machine-gun; it also had single cupola on the centreline of the turret. The AA-turret was removed from A6E1. However it was also shown that the suspension and the gunnery arrangements were distinctly inferior to those of the Mark II. It was therefore decided to discontinue the development of the type and use the three vehicles merely as test-beds for the automotive parts. In 1929 Vickers submitted three alternative suspension designs, which were fitted to the respective prototypes; one of these, tried on A6E3, involved a fundamental reconstruction of the hull. None proved able to provide a stable gun platform. Only in 1934 was a satisfactory type was fitted by a specialised firm.

The disappointments in the A6 design led to a new design, the "Medium Mark III", being ordered in 1928 and constructed from 1930. It was similar to the A6 design but featured a new turret and improved armour. The turret had a flat gun mantlet and a bulge at the back to hold a radio set. The secondary machine-gun turrets were moved more to the front to shift the centre of gravity of the entire vehicle forward to improve its stability. Larger brakes were fitted. Trials were completed of the first two prototypes in 1933. The type was reliable and provided a good gun platform. However, it still suffered from poor suspension design: while road speed had been increased to thirty miles per hour, the bogies were often overloaded during cross-country travel. Three Mark IIIs were built, one by Vickers and two by the Royal Ordnance Factory at Woolwich: Medium III E1, E2 and E3. The third had an improved suspension and in 1934 the vehicles were taken into use by the HQ of the Tank Brigade. However, no orders followed due to the high price of the machines.

One of the Medium Mark III's was fitted as a command vehicle with an extra radio aerial around the turret. This was used by Brigadier Percy Hobart for the Salisbury Plain exercises during 1934.

British Tankettes and Light Tanks of the 1920's and 1930's

In the 1920's, only in Britain did the idea of establishing armoured forces as a decisive arm of the Army in their own right take root – but even in Britain it cannot be said that there was a great deal of enthusiasm – and it must also be remembered that Britain's principal defence commitments were directed to the maintenance of order on the fringes of the Empire. And many of the pundits suggested that in any case, even if tanks were needed in the next war as in the last, they would soon be knocked out by anti-tank guns. Machineguns were seen as of more importance on the battlefield by many – and in 1925 two British designers made separate approaches to the same solution.

Major Giffard Le Quesne Martel

Major Giffard Martel, backed by the resources of the motor vehicle manufactuer William Morris, and John Carden, working in the garage of a Mr. Loyd, built machinegun carriers that were cheap, small and easy to mass produce. Both aimed to offer the option of fighting mounted or dismounted. Carden and Loyd rapidly took the lead in development and managed to get the British Army interested in their vehicle for reconnaissance purposes as well as for a weapons carrier. By doing so they blurred the original concept, for the Army called Carden-Loyd's carriers "Tankettes" and thus gave the impression that the Tank Corps and not the Infantry had a vested interest in them.

Sir John Valentine Carden, 6th Baronet, MBE (6 February 1892 – 10 December 1935) was an English tank and vehicle designer. He was the sixth Baronet of Templemore, Tipperary, from 1931. Born in London, Carden was a talented, self-taught engineer, with an ability to put his ideas to practical use. From 1914 to 1916, he ran a company that manufactured light passenger-cars under the brand Carden. The company’s first model was a cyclecar, with seating only for the driver. During the First World War, Carden served in the Army Service Corps and gained the rank of Captain, acquiring experience with vehicles such as tracked Holt tractors. After the war, he returned to car manufacturing but sold his original design and factory to Ward and Avey who renamed it the AV. He then designed a new cyclecar and started manufacture at Ascot but at the end of 1919 sold the design to E. A. Tamplin who continued manufacture as the Tamplin car. A further design followed with a two seat fibreboard body. Carden even sold one of these to King Alfonso XIII of Spain before selling the company to new owners in 1922 who renamed it the New Carden.

Two or three years later, Carden met car-designer Vivian Loyd and the two started a small company in Chertsey named Carden-Loyd, working on light, tracked vehicles for military use. Carden was reportedly described as an “introvert engineering genius”, while Loyd was conversely described as an “extrovert engineer-salesman”. What brought the pair real success was a tankette design: the first Carden-Loyd One-Man Tankette, which was designed in 1925. In the next two years, it was developed into Marks I, II and III, and later, two-man tankette models Mark IV and Mark V. All were built in small numbers but were very promising, and, as a result, Carden-Loyd was bought by Vickers-Armstrongs in March 1928. Carden himself was employed by Vickers as the technical director. The pair continued developing their tankette model, eventually creating their best-known design, the Mark VI. It became the first successful design for that vehicle type in the world, and a classic one, several hundred being produced and exported to 16 countries. Many foreign tankette models developed later were said to be inspired by the Mark VI.

Sir John Carden at Heston Airport 3 October 1935; L. E. Baynes on left, Stephen Appleby on right

Carden and Loyd also designed light tanks, such as the well-known Vickers-Armstrongs Commercial Light Tanks series (used, for example, in Belgium) and the British Army’s Light Tanks, including the Light Tank Mk VI (one of Carden’s last designs). The pair also developed the world’s first amphibious tank, the Vickers-Carden-Loyd Amphibian Tank, and played a role in the development of the Vickers E tank model. Aside from tanks, Carden and Loyd also developed several light artillery tractors and carriers, including the VA D50 model, which was a prototype of the Bren Carrier. Carden’s interest in flying also led him to build an ultralight plane based on the French “Flying Flea”, using a modified Ford engine uprated from 10 bhp to 31 bhp. In 1935, Carden started Carden Aero Engines Ltd., an aircraft engine manufacturer. A partnership with L.E. Baynes led to the founding of Carden Baynes Aircraft Ltd., which produced gliders of Baynes’ design fitted with auxiliary engines. John Carden was killed in an air crash near Tatsfield, Surrey on 10 December 1935, while flying on a Sabena airliner.

Vivian Loyd (1894-1972) was born in Berkshire, to a family of Welsh origin. He was educated at Wellington , after which he worked in a bank in Canada. After the outbreak of World War I he returned to the UK and served in the British artillery. During the war he served in, amongst other locations, Mesopotamia , where he contracted tuberculosis , which was the reason for his subsequent health problems. After the war, in 1922, Loyd founded a small car manufacturing company together with A. Lord where they built passenger cars of Loyd’s design, under the brand name Loyd-Lord (likely a tongue in cheek reference to the Rolls-Royce label). Falling into debt, the company was liquidated in 1924. In 1922 or 1923 Loyd met self-taught engineer John Carden , with whom he founded the small Carden-Loyd Tractor Company in Chertsey near London. Together they started working on the design of tracked vehicles, primarily with military applications.

A small low-res scan of the young Vivian Loyd, from Foss & McKenzie’s excellent work: ‘The Vickers Tanks’

Carden was chief engineer on the team while Loyd was mainly responsible for organizational issues and marketing. Loyd remained in the shadow of John Carden, and after Carden’s death in a plane crash in 1935, relations between Vickers management and Loyd deteriorated. In September 1938 Loyd finally left Vickers and founded his own company, Vivian Loyd & Co. In August 1938 he presented a prototype of a low-cost light tracked artillery tractor, the Loyd Carrier. It was ordered by the British army during the war and more than 26,000 units were built, 2,790 from Loyd’s factory. After the war, Loyd tried to offer the tractor to the civilian market. Loyd died in 1972 at his farm in Berkshire. He was married three times and had two sons and two daughters.

Carden and Loyd rapidly took the lead in development and managed to get the British Army interested in their vehicle for reconnaissance purposes as well as for a weapons carrier. By doing so they blurred the original concept, for the Army called Carden-Loyd’s carriers “Tankettes” and thus gave the impression that the Tank Corps and not the Infantry had a vested interest in them. In practice, carriers extended the range and safety of infantrymen and gave them a golden opportunity to raise their speed to that of the tank arm by acting as a team whicj could be formed around the principal armoured fighting vehicle – the tank. This was the essence of the "All Armoured Idea", which few at the time really understood, and which many more traditionally minded soldiers reviled as the "All Tank Idea."

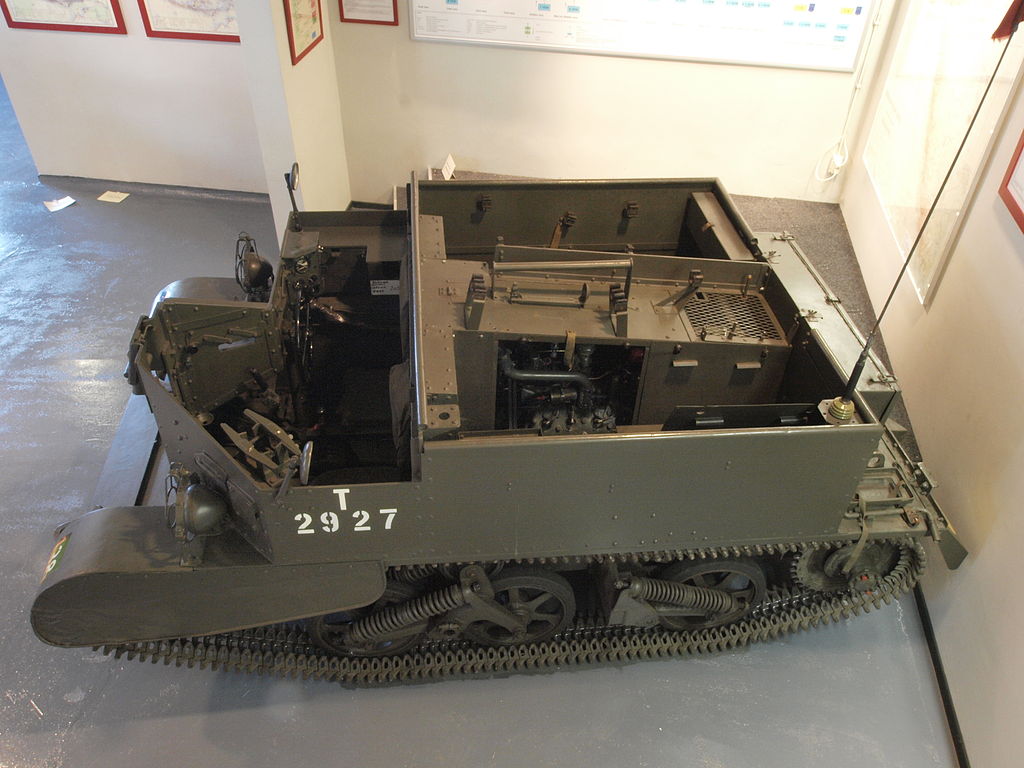

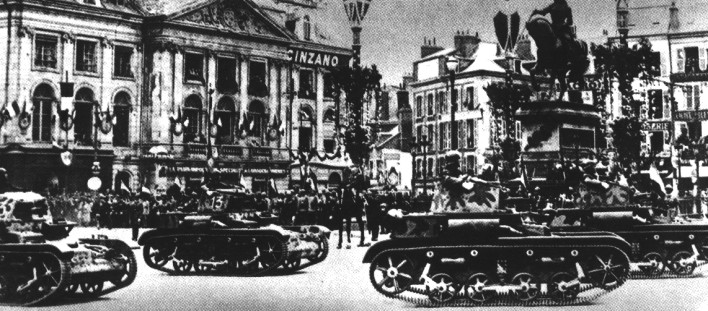

Steadily, these versatile little Carriers were improved and for lack of anything better, played an important part in reconnaissance and protection duties for the main force of medium tanks during the first British Armoured Force experiements of 1927 and 1928. Carden-Loyd would be bought out by Vickers in 1928. The Carden0Loyd carriers grew into Light Tanks, while foreign purchasers came forward to buy the basic vehicle and adapt it in their own factories to suit their own requirements. France's UE, Russia's T-27 and the Italian CV-33/35 came closer to the weapons carrier concept, although they are often referred to as tanks. In Britain, the weapon carrier would return to the Infantry in 1935 with the introduction of the Universal Carrier, a tracked and lightly armoured carrier which would become ubiquitos within the British Army through WW2.

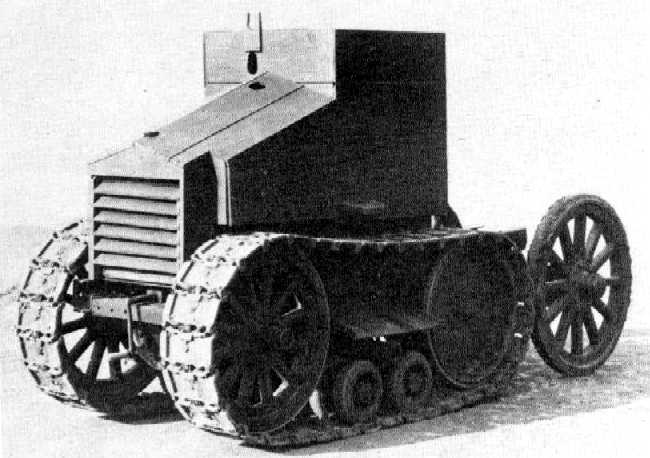

Morris-Martel Tankette - 1927

The Morris-Martel was a British inter-war tankette developed from prototypes designed by Lieutenant-General Sir Giffard Le Quesne Martel. Martel decided he would build a small tank himself and he did this in the garage of his house near Camberley. He took the engine from an old Maxwell car, the back-axle of a Ford lorry and a set of tracks made for him by the Roadless Traction Company. He showed the result of in 1925. It was only eight feet long by five feet high but it worked and the War Office ordered four to be made by William Morris.

Morris-Martel One Man Tankette

Intended for reconnaissance, eight in all were constructed for the Experimental Mechanized Force and were tested against experimental models of the Carden Loyd tankette - built by John Carden and Vivian Loyd as a response to Martel's work - on Salisbury plain in 1927. The project was abandoned after testing with the Carden Loyd design chosen instead, however during its short existence the tankette attracted "quite a lot of publicity" and was a pioneer of the tankette concept.

Carden Loyd Tankette – 1927 to 1935

The Carden Loyd tankettes were a series of British pre-World War II tankettes, the most successful of which was the Mark VI, the only version built in significant numbers. It became a classic tankette design worldwide, was licence-built by several countries and became the basis of several designs produced in several different countries.

The Carden Loyd tankette came about from an idea of the British military engineer and tank strategist Major Giffard LeQuesne Martel, who started designing and building a small tankette as a private project. He built a one-man tank in his garage from various parts and showed it to the War Office in the mid-1920s. With the publication of the idea, other companies produced their own interpretations of the idea. One of these was Carden-Loyd Tractors Ltd, a firm founded by Sir John Carden and Vivian Loyd and later purchased by Vickers-Armstrong. Besides one-man vehicles they also proposed two-man vehicles which turned out to be a more effective and popular idea. Vickers-Armstrong manufactured and marketed vehicles of the latter type worldwide.

Considered a reconnaissance vehicle and a mobile machine gun position, the Mark VI was the final stage of development of the Carden- Loyd series of tankettes. The Carden Loyd tankette can also be considered an early prototype for the Universal Carrier (Bren Gun Carrier).

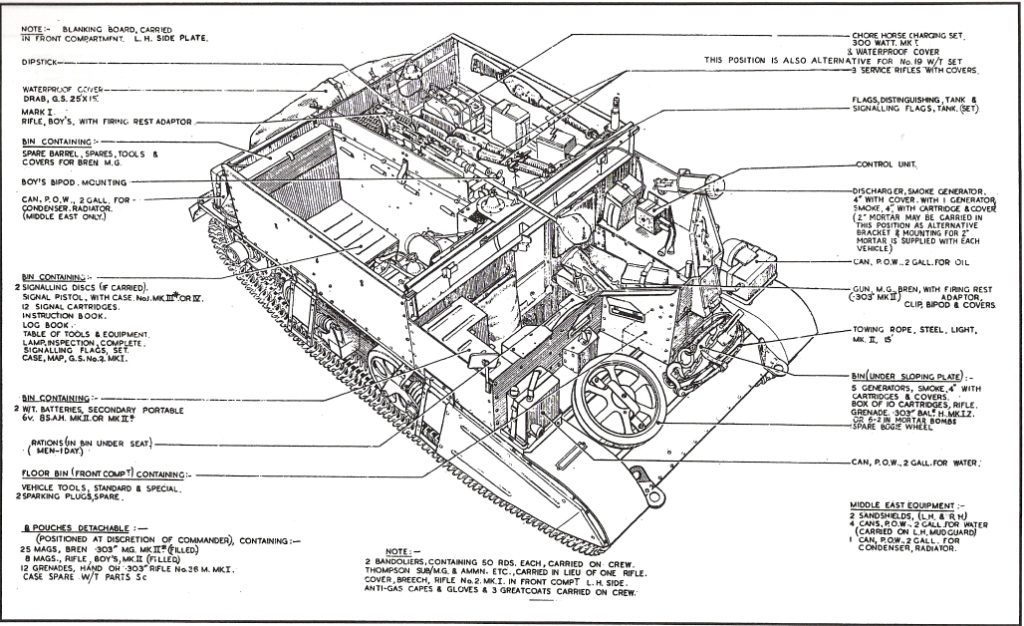

Production started in 1927 and lasted until 1935. From 1933 to 1935 some 450 Carden-Loyd tankettes were manufactured by the Royal Ordnance Factories. The British Army used at least 325 Mark VI tankettes in several variants, mostly as machine gun carriers, but also as light gun tractors, mortar carriers or smoke projector vehicles. They were also sold and/or licensed in considerable numbers to Poland, Czechosolvakia, the Soviet Union, Bolivia, Japan, Italy and Canada. In addition, the Carden Loyd tankettes were also supplied in small numbers to France, India, Italy, the Netherlands, Siam, chile, the Reoublic of China, Finland and Portugal. The French unarmed Renault UE carrier was also based on the Carden Loyd design. The design of the German Panzer I light tank was somewhat influenced by the Carden Loyd tankette (apparently as a result of German military cooperation with the Soviet Union).

The Mark VI was the final stage of development of the Carden- Loyd series of tankettes.

The Carden-Loyd Mk VI tankette weighed 1.5 tons, was 8 ft in length, 6ft 6in wide and had a height of 4ft. With a crew of 2, it was armed with a single .303 Vickers machinegun with 1,000 rounds. The 4 cylinder 22.5 hp Ford Model-T petrol engine with a 10 gallon fuel tank gave the tankette a range of 100 miles with a 30mph maximum road speed.