Interesting russian article about armor

Re: Interesting russian article about armor

I would say that that something doesn't fit when comparing Soviet thick HH armor to German, or the armor made from UK, US or France during the war.

It is estrange that only Russia were able to make thick and very hard armor, in large numbers and with better ballistic characteristics (for 0º to 40º impact angles at least)

All the other countries had to quench, a time consuming process, thick armor in order to reduce hardness and improve ballistic resistance.

So had soviets any secret in its armor to not require this process?

Usually, measuring projectile penetration follows some rules depending the country: the projectile must pass trough the plate at least in part, the explosive -if it exist- must burst, a number of penetrations are required, etc. Each country has may have different requirements.

Nevertheless, when measuring plate resistance the criteria are different. Here we need to know how much protection it will offer. For example Germans stated that “the eye must be safe”, which is the same as saying that the plate can bulge but not spalling. And again there are differences between countries about what is considered a safe armor plate

Usually a plate is considered defeated before the projectile fulfill penetration criteria. Usually the difference in strike velocity between plate defeated and projectile penetrations is not too much. Except when the plate is prone to spalling, which is the case of thick HH armor.

Thick HH armor begins spalling at a strike velocity significantly lesser than the one the projectile needs to meet penetration criteria.

So, considering German projectile penetration criteria for example, PzGr39 penetrates less HH armor than MH armor.

But if you consider the ballistic limit of the plate, it is lower for HH armor than MH armor, because earlier spalling. And then if you need complete protection from HH armor, you need more thickness of steel than MH armor.

Of course, Russian surely preferred spalling than a bursting PzGr39 inside the tank.

It is estrange that only Russia were able to make thick and very hard armor, in large numbers and with better ballistic characteristics (for 0º to 40º impact angles at least)

All the other countries had to quench, a time consuming process, thick armor in order to reduce hardness and improve ballistic resistance.

So had soviets any secret in its armor to not require this process?

Usually, measuring projectile penetration follows some rules depending the country: the projectile must pass trough the plate at least in part, the explosive -if it exist- must burst, a number of penetrations are required, etc. Each country has may have different requirements.

Nevertheless, when measuring plate resistance the criteria are different. Here we need to know how much protection it will offer. For example Germans stated that “the eye must be safe”, which is the same as saying that the plate can bulge but not spalling. And again there are differences between countries about what is considered a safe armor plate

Usually a plate is considered defeated before the projectile fulfill penetration criteria. Usually the difference in strike velocity between plate defeated and projectile penetrations is not too much. Except when the plate is prone to spalling, which is the case of thick HH armor.

Thick HH armor begins spalling at a strike velocity significantly lesser than the one the projectile needs to meet penetration criteria.

So, considering German projectile penetration criteria for example, PzGr39 penetrates less HH armor than MH armor.

But if you consider the ballistic limit of the plate, it is lower for HH armor than MH armor, because earlier spalling. And then if you need complete protection from HH armor, you need more thickness of steel than MH armor.

Of course, Russian surely preferred spalling than a bursting PzGr39 inside the tank.

Re: Interesting russian article about armor

It was rather a choice, influenced by their heat treatment capabilities, adjusted to their demands in order to find a satisfactory solution to defeat their native projectile designs and not some sort of secret monopole.It is estrange that only Russia were able to make thick and very hard armor, in large numbers and with better ballistic characteristics (for 0º to 40º impact angles at least)

-

critical mass

- Member

- Posts: 740

- Joined: 13 Jun 2017, 15:53

- Location: central Europe

Re: Interesting russian article about armor

Notice that the soviets were not capable of producing large quantities of thick RHA plate treated to high hardness. The IS2 program showed they went into trouble with plates in 100 to 120mm thickness range (42-S and 42SM later), already. Most very thick armor was cast (70-L, later 71-L), not rolled. Some amount of very thick RHA plate was made for experimental firing purposes, only.

I think people greatly underestimate how difficult it was to make a high quality plare, in 80 to 150mm thick gauge, in rolled hardened form.

Cast armmor can be almost as good as RHA in low obliquity, where the transverse directional tensile strength is not much different from cross rolled RHA plate and most easily manipulated by hardness alone. But at acute angles, a RHA plate benefits from crystalline direction and directional manipulation of longitudinal and latitudinal tensile strengths caused by mechanical treatment (cross rolling). Cast armor cannot compare here to RHA.

I think people greatly underestimate how difficult it was to make a high quality plare, in 80 to 150mm thick gauge, in rolled hardened form.

Cast armmor can be almost as good as RHA in low obliquity, where the transverse directional tensile strength is not much different from cross rolled RHA plate and most easily manipulated by hardness alone. But at acute angles, a RHA plate benefits from crystalline direction and directional manipulation of longitudinal and latitudinal tensile strengths caused by mechanical treatment (cross rolling). Cast armor cannot compare here to RHA.

Re: Interesting russian article about armor

T-34 50mm cast turrets had equivalent resistance to penetration than 40mm RHA plate, both with similar high hardness, when tested with Russian 45mm uncapped AP.

Reading the translation of this interesting Russian article, I would think that during Barbarossa even low velocity 7,5cm guns belonging to Panzer IV and Stug had a chance of penetration against T-34 side turrets at close range, considering its favourable t/d and better quality ammunition than Russian 45mm.

7,5 Pzgr. rot would pierce 38mm @30º at 500m from German tests, in bursting condition.

At 0.7 t/d, high hardness armour was inferior to medium hardness one. If T-34 cast turrets were tested with 7,5cm APCBC ammo its armor performance would be even less that when thested with 45mm ammo.

Reading the translation of this interesting Russian article, I would think that during Barbarossa even low velocity 7,5cm guns belonging to Panzer IV and Stug had a chance of penetration against T-34 side turrets at close range, considering its favourable t/d and better quality ammunition than Russian 45mm.

7,5 Pzgr. rot would pierce 38mm @30º at 500m from German tests, in bursting condition.

At 0.7 t/d, high hardness armour was inferior to medium hardness one. If T-34 cast turrets were tested with 7,5cm APCBC ammo its armor performance would be even less that when thested with 45mm ammo.

-

critical mass

- Member

- Posts: 740

- Joined: 13 Jun 2017, 15:53

- Location: central Europe

Re: Interesting russian article about armor

Considering that 38mm was 110 to 125kg/mm^2plate and that T45 HHA is treated to 150-160kg/mm^2 hardness, one would expect that the actual penetration of the low velocity 7.5cm pzgr rot against T34 plate may be up to 12% lower than rated, but then again, this assumes that the scaling rate of the target materials was similar, a presumption which is invalid. However, one needs to point out that the Pzgr rot, too, is less capable of staying intact and may very well be broken up by 8-S unless fairly low velocities and obliquities (historically it did broke up vs 110-125kg/mm^2 at approx. 500m/s @30°). Whether or not that is sufficient to provide immunity is not known to me with the data at hand.

The resistence of 45mm HHA was recorded as very poor against overmatching attack due to inferior scaling and ease of adiabatic shear failure of the too hard target material. The issue was not unknown to the soviets. 3 sample plates were manufactured for state acceptance, which required it to resist vs 45mm Br240 at short range and resist to 76mm at long range without plate cracking nor discing (3 times large calibre holes for the soviets, 2 cal for everybody else). All three plates failed against soviet 76.2mm BR350 down to the lowest velocity tested (<500m/s, limit not found). This failure caused the specifications of 8-S grade HHA steel to be rewritten so that they got rid of the 76.2mm overmatching test in order to pass the armor, relying solely on the ability to resist domestic 45mm shell. Russian 45mm -much like older, uncapped and monobloc 5cm Pzgr Gg are really not a severe test for the 8-S HHA plate, which acted like face hardened plate vs inferior AP shell. Br-240 couldn´t penetrate 45mm at 0° and muzzle velocity due to full shatter, so what´s the purpose of testing it vs 50mm HHA cast?

When 45mm 8-S (T34) plate was tested at the soviet prooving ground in autumn 1942 vs capped 50mm Pzgr39, the PSP limit was 360m/s, which was lower than anybody anticipated it. The best PSP plate tested gave in at 415m/s to this projectile (to compare it, the 45mm Br-240 required 895m/s for PSP vs the same target at 0°).

Judging by the informtion at hand, one cannot rule out the possibility that even L/24 75mm Spgr34 may do the job against HHA 50mm turret plate. 88mm Spgr was found to be sufficient to clear the 75mm cast T34 turret from the hull with a hit square on due to insufficient resistence to shock. 75mm Spgr will be less severe but then again, if it deals with 50mm, that´s still more than anough. Even against 75mm cast HHA, it likely will still have sufficient force to spall within the turret.

The resistence of 45mm HHA was recorded as very poor against overmatching attack due to inferior scaling and ease of adiabatic shear failure of the too hard target material. The issue was not unknown to the soviets. 3 sample plates were manufactured for state acceptance, which required it to resist vs 45mm Br240 at short range and resist to 76mm at long range without plate cracking nor discing (3 times large calibre holes for the soviets, 2 cal for everybody else). All three plates failed against soviet 76.2mm BR350 down to the lowest velocity tested (<500m/s, limit not found). This failure caused the specifications of 8-S grade HHA steel to be rewritten so that they got rid of the 76.2mm overmatching test in order to pass the armor, relying solely on the ability to resist domestic 45mm shell. Russian 45mm -much like older, uncapped and monobloc 5cm Pzgr Gg are really not a severe test for the 8-S HHA plate, which acted like face hardened plate vs inferior AP shell. Br-240 couldn´t penetrate 45mm at 0° and muzzle velocity due to full shatter, so what´s the purpose of testing it vs 50mm HHA cast?

When 45mm 8-S (T34) plate was tested at the soviet prooving ground in autumn 1942 vs capped 50mm Pzgr39, the PSP limit was 360m/s, which was lower than anybody anticipated it. The best PSP plate tested gave in at 415m/s to this projectile (to compare it, the 45mm Br-240 required 895m/s for PSP vs the same target at 0°).

Judging by the informtion at hand, one cannot rule out the possibility that even L/24 75mm Spgr34 may do the job against HHA 50mm turret plate. 88mm Spgr was found to be sufficient to clear the 75mm cast T34 turret from the hull with a hit square on due to insufficient resistence to shock. 75mm Spgr will be less severe but then again, if it deals with 50mm, that´s still more than anough. Even against 75mm cast HHA, it likely will still have sufficient force to spall within the turret.

-

Yoozername

- Member

- Posts: 2619

- Joined: 25 Apr 2006, 16:58

- Location: Colorado

Re: Interesting russian article about armor

Interesting test....

Brief report written at the end of June 1944 by the Pz.Jg.Abt.15 (L), unit integrated in the Luftwaffen-Felddivision 15, where the effects of 5 cm projectiles fired against the Russian tank IS-2 are described.

Brief report written at the end of June 1944 by the Pz.Jg.Abt.15 (L), unit integrated in the Luftwaffen-Felddivision 15, where the effects of 5 cm projectiles fired against the Russian tank IS-2 are described.

29.6.1944

Panzerjägerabteilung 15 (L)

In reference to : 5 cm anti-tank gun against "Josef Stalin"

Directed to : Heeresgruppe Südukraine Stopak .

In the sector of the 1. Romanian Real Division the 1./Pz.Jg.Abt.15 (L) has carried out firing tests with an anti-tank gun of 5 cm against the new Russian tank "Josef Stalin". At distances of 210 and 110 meters against the turret ring and against the turret total armor perforations have been achieved.

Shooting against the sides of the vehicle at those same distances has not been successful. Two projectiles fired on the traction wheels punctured them and projectiles penetrated the engine compartment through the bushings.

At a distance of 60 meters the projectile is embedded in the lateral shield causing a dent in the shield of 2 centimeters deep.

Signed:

Major and Commander of the Abteilung

-

critical mass

- Member

- Posts: 740

- Joined: 13 Jun 2017, 15:53

- Location: central Europe

Re: Interesting russian article about armor

What is the source of this snippet? There are some issues here: A) why 210 and 110m, instead of 200 and 100...?

And what exactly is referred to here with the lateral shield?

And what exactly is referred to here with the lateral shield?

- Alejandro_

- Member

- Posts: 404

- Joined: 21 May 2003, 14:26

- Location: UK

- Contact:

Re: Interesting russian article about armor

Edited.

Last edited by Alejandro_ on 26 Mar 2019, 16:36, edited 1 time in total.

- Alejandro_

- Member

- Posts: 404

- Joined: 21 May 2003, 14:26

- Location: UK

- Contact:

Re: Interesting russian article about armor

Here is the original in German. The shots against the sides were done against a standard vehicle, thus no shields. It is referring to the side armour -probably an error of the automatic translator-.What is the source of this snippet?

http://panzer-elmito.org/otros/enemigo/ ... -29_D.html

-

critical mass

- Member

- Posts: 740

- Joined: 13 Jun 2017, 15:53

- Location: central Europe

Re: Interesting russian article about armor

Thanks for the link. Yes, it´s apparently a translation mistake. At 60m, the projectile failed to perforate the side armor and just dented it. It´s a significant observation here, that the 5cm Pzgr39 did completely perforate the cast turret armor at 110m and 220m but failed at all distances (210, 110 and 60m) against the presumably welded, RHA side armor. Although obliquities are not explicitely stated, one must reckon with the possibility that "günstige Auftreffwinkel" is referring to more benign angles than the commonly quoted 30° (very low target angle, at least).

-

Yoozername

- Member

- Posts: 2619

- Joined: 25 Apr 2006, 16:58

- Location: Colorado

Re: Interesting russian article about armor

That is my impression. There are no 'shields'. They are just referring to the normal armored plates. Were there ever any 'shields' like skirt armor, etc.?

Commas may have been needed.

At distances of 210 and 110 meters (comma) against the turret ring and against the turret (comma) total armor perforations have been achieved.

Basically, wait till very short range, and aim for turret (side) and turret ring areas.

Commas may have been needed.

At distances of 210 and 110 meters (comma) against the turret ring and against the turret (comma) total armor perforations have been achieved.

Basically, wait till very short range, and aim for turret (side) and turret ring areas.

Re: Interesting russian article about armor

I've found the definition of the "Vпкп" ballistic limit used by the soviets post-WW2: https://thesovietarmourblog.blogspot.co ... art-2.html

PROTECTION CRITERIA

The Soviet criteria for armour protection has a specific definition that distinguishes it from the protection criterion used by foreign armies. Under the Soviet definition, the term "кондиционного поражения" or "nominal defeat" is used. This term is used to describe the defeat of the tank armour by the breakdown of its structure, achieved by exceeding the limits of its strength. It is equivalent to a partial penetration under the definitions of other testing standards. For example, if spall failure is detected, it is indicative that the shock energy from an impacting projectile was high enough to overcome the tensile strength of the armour material. However, spall must not be ejected from the armour. Similarly, if ductile fractures are detected, it is indicative that another form of structural failure has occurred. From external observation, the detection of nominal armour defeat can be carried out by identifying surface cracks or cracked bumps on the back surface of the armour plate.

This is different from perforating the armour plate, for which the term "сквозное поражение" (perforating defeat) is used. The velocity limit of armour perforation, "пределе сквозное поражение", is expressed as "Vпсп". The definition of the limit of armour perforation in Soviet and Russian technical literature is the same as in all other works on the subject. The perforation limit of a penetrator is the maximum armour thickness where breakthrough is possible for a given impact velocity. This type of armour perforation yields a very weak post-perforation effect. After achieving breakthrough, the residual penetrator has almost no energy left, so it either sticks to the exit crater or falls to the ground and does not contribute to damaging the internal equipment or crew of a tank, and the energy of the spall ejected from the back surface of the armour is also very low. Due to this, it can be referred to as initial perforation, which distinguishes it from more energetic cases of armour perforation where a large amount of residual energy is retained after breaking through the armour.

In the textbook "Частные Вопросы Конечной Баллистики" (Particular Questions of Terminal Ballistics), it is stated that the rule for converting from the limit of nominal armour defeat to the limit of armour perforation is to subtract 10mm of RHA from the physical armour thickness. To do the opposite, the reverse is applied. For example, if a KE round can achieve nominal defeat on 150mm RHA sloped at 60 degrees, it only achieves armour perforation on 140mm RHA sloped at 60 degrees. According to the textbook, the 10mm RHA thickness was determined by practical experience.

It is also stated that for composite armour, 20mm of additional physical thickness on the back plate is required to ensure a transition from guaranteed armour perforation to nominal armour defeat. For example, if a hypothetical two-layer spaced armour target is guaranteed to be perforated by a long rod penetrator, adding another 20mm of physical thickness to the back plate will prevent a guaranteed penetration and instead leave the armour vulnerable only to nominal defeat. The inverse is also true. If the same spaced armour can only be nominally defeated by a long rod penetrator, reducing the back plate thickness by 20mm will guarantee that the penetrator perforates the armour.

It is important to mention that by definition, nominal defeats can only occur for finite thickness plates. A semi-infinite thickness armour block effectively prevents any back surface failure by its nature, and hence, it is impossible for a nominal defeat to be achieved. As such, it is fundamentally meaningless to compare the thickness limit of nominal defeat with thickness limit (penetration depth) of a KE penetrator into semi-infinite steel.

Along with nominal defeat and initial perforation, another type of armour defeat is the so-called "guaranteed perforation". The guaranteed perforation is defined as the minimum armour thickness that can be perforated by the given penetrator at the given velocity. It can also be defined as the minimum velocity where a given thickness of armour can be perforated. Guaranteed armour perforation is usually accompanied by strong post-perforation effects.

Note that the three distinct types of armour defeat - nominal defeat, initial perforation, guaranteed perforation - are all important metrics and the relationship between each type must be understood to make sense of how effective thickness is calculated for tank armour.

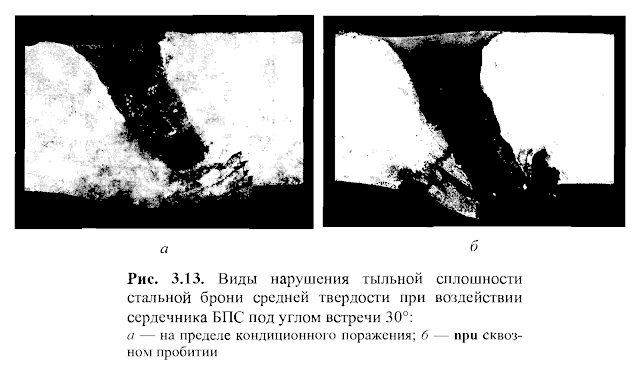

The photo on the left below (а) shows the condition of an RHA plate after being subjected to an impact from an APFSDS round at the velocity of its nominal defeat. The stress exceeded the tensile strength limit of the armour material which resulted in a spall failure, but without the ejection of spall from the plate. Only a cracked bump has formed on the back surface of the plate. The photo on the right below (б) shows an example of full armour perforation where fragments are ejected from the armour plate, which requires a higher impact velocity to achieve. The armour obliquity is 30 degrees in both examples.

If the limit of nominal defeat is reached ("пределе кондиционного поражения"), this is enough for the armour to be considered defeated, and the impact velocity at which the reference threat achieves this is referred to as the velocity limit of nominal defeat, "Vпкп" (Vpkp).

-

Formien1939

- New member

- Posts: 1

- Joined: 18 Jan 2021, 12:23

- Location: New York

Re: Interesting russian article about armor

In addition to NIJ standard 0101.04 and 0101.06, there are also HOSDB, VPAM 2006, German Schutz class, Russian GOST R 50744-95, European PrEN ISO14876-2, all of which have similar levels of protection against high-speed projectiles.Peasant wrote: ↑23 May 2020, 16:39I've found the definition of the "Vпкп" ballistic limit used by the soviets post-WW2: https://thesovietarmourblog.blogspot.co ... art-2.html

PROTECTION CRITERIA

The Soviet criteria for armour protection like on this site has a specific definition that distinguishes it from the protection criterion used by foreign armies. Under the Soviet definition, the term "кондиционного поражения" or "nominal defeat" is used. This term is used to describe the defeat of the tank armour by the breakdown of its structure, achieved by exceeding the limits of its strength. It is equivalent to a partial penetration under the definitions of other testing standards. For example, if spall failure is detected, it is indicative that the shock energy from an impacting projectile was high enough to overcome the tensile strength of the armour material. However, spall must not be ejected from the armour. Similarly, if ductile fractures are detected, it is indicative that another form of structural failure has occurred. From external observation, the detection of nominal armour defeat can be carried out by identifying surface cracks or cracked bumps on the back surface of the armour plate.

This is different from perforating the armour plate, for which the term "сквозное поражение" (perforating defeat) is used. The velocity limit of armour perforation, "пределе сквозное поражение", is expressed as "Vпсп". The definition of the limit of armour perforation in Soviet and Russian technical literature is the same as in all other works on the subject. The perforation limit of a penetrator is the maximum armour thickness where breakthrough is possible for a given impact velocity. This type of armour perforation yields a very weak post-perforation effect. After achieving breakthrough, the residual penetrator has almost no energy left, so it either sticks to the exit crater or falls to the ground and does not contribute to damaging the internal equipment or crew of a tank, and the energy of the spall ejected from the back surface of the armour is also very low. Due to this, it can be referred to as initial perforation, which distinguishes it from more energetic cases of armour perforation where a large amount of residual energy is retained after breaking through the armour.

In the textbook "Частные Вопросы Конечной Баллистики" (Particular Questions of Terminal Ballistics), it is stated that the rule for converting from the limit of nominal armour defeat to the limit of armour perforation is to subtract 10mm of RHA from the physical armour thickness. To do the opposite, the reverse is applied. For example, if a KE round can achieve nominal defeat on 150mm RHA sloped at 60 degrees, it only achieves armour perforation on 140mm RHA sloped at 60 degrees. According to the textbook, the 10mm RHA thickness was determined by practical experience.

It is also stated that for composite armour, 20mm of additional physical thickness on the back plate is required to ensure a transition from guaranteed armour perforation to nominal armour defeat. For example, if a hypothetical two-layer spaced armour target is guaranteed to be perforated by a long rod penetrator, adding another 20mm of physical thickness to the back plate will prevent a guaranteed penetration and instead leave the armour vulnerable only to nominal defeat. The inverse is also true. If the same spaced armour can only be nominally defeated by a long rod penetrator, reducing the back plate thickness by 20mm will guarantee that the penetrator perforates the armour.

It is important to mention that by definition, nominal defeats can only occur for finite thickness plates. A semi-infinite thickness armour block effectively prevents any back surface failure by its nature, and hence, it is impossible for a nominal defeat to be achieved. As such, it is fundamentally meaningless to compare the thickness limit of nominal defeat with thickness limit (penetration depth) of a KE penetrator into semi-infinite steel.

Along with nominal defeat and initial perforation, another type of armour defeat is the so-called "guaranteed perforation". The guaranteed perforation is defined as the minimum armour thickness that can be perforated by the given penetrator at the given velocity. It can also be defined as the minimum velocity where a given thickness of armour can be perforated. Guaranteed armour perforation is usually accompanied by strong post-perforation effects.

Note that the three distinct types of armour defeat - nominal defeat, initial perforation, guaranteed perforation - are all important metrics and the relationship between each type must be understood to make sense of how effective thickness is calculated for tank armour.

The photo on the left below (а) shows the condition of an RHA plate after being subjected to an impact from an APFSDS round at the velocity of its nominal defeat. The stress exceeded the tensile strength limit of the armour material which resulted in a spall failure, but without the ejection of spall from the plate. Only a cracked bump has formed on the back surface of the plate. The photo on the right below (б) shows an example of full armour perforation where fragments are ejected from the armour plate, which requires a higher impact velocity to achieve. The armour obliquity is 30 degrees in both examples.

If the limit of nominal defeat is reached ("пределе кондиционного поражения"), this is enough for the armour to be considered defeated, and the impact velocity at which the reference threat achieves this is referred to as the velocity limit of nominal defeat, "Vпкп" (Vpkp).

Re: Interesting russian article about armor

Is there actually any blog on Soviet equipment that is not based on exaltation, I wonder.https://thesovietarmourblog.blogspot.co ... art-2.html

Re: Interesting russian article about armor

I think I have solved the puzzle.

This chart here presents a noticeably superior performance of the 122mm BR-471B shell against RHA at low obliquity compared to most other sources.

From the British experiments of firing different caliber shot against RHA, with a bit of math we can extract the ductile-brittle transition point as a function of T/D ratio and attacking caliber.

As can be seen in the Excel chart, the plate made according to MIL-S-12560B standard will have excessive hardness to resist a 122mm shell, leading to premature ejection of spall relative to an RHA plate with a hardness under the limit. This issue disappears for thicknesses over 7-8in.

At this point one could finish the analysis and conclude that the ballistic limit curves shown here are correct, if we didn't already know that they're incorrect from other examples of performance of soviet blunt headed shells under similar conditions.

The most likely explanation I have is that the trials were not carried out against plates above 6in. thick, as greater thicknesses of rolled armour were not expected to be used on any vehicle, as the US went with cast armour for particularly thick sections instead, and what we see here is an erroneous extrapolation of the data.

Edit: Alt thread.

This chart here presents a noticeably superior performance of the 122mm BR-471B shell against RHA at low obliquity compared to most other sources.

From the British experiments of firing different caliber shot against RHA, with a bit of math we can extract the ductile-brittle transition point as a function of T/D ratio and attacking caliber.

As can be seen in the Excel chart, the plate made according to MIL-S-12560B standard will have excessive hardness to resist a 122mm shell, leading to premature ejection of spall relative to an RHA plate with a hardness under the limit. This issue disappears for thicknesses over 7-8in.

At this point one could finish the analysis and conclude that the ballistic limit curves shown here are correct, if we didn't already know that they're incorrect from other examples of performance of soviet blunt headed shells under similar conditions.

The most likely explanation I have is that the trials were not carried out against plates above 6in. thick, as greater thicknesses of rolled armour were not expected to be used on any vehicle, as the US went with cast armour for particularly thick sections instead, and what we see here is an erroneous extrapolation of the data.

Edit: Alt thread.