The benefits of interleaved & overlapping road wheels?

The benefits of interleaved & overlapping road wheels?

I guess it would make sense to separate the interleaved wheel design (of the early Tiger and the Panther) from the overlapping wheel design (of the late Tiger and Tiger 2), as the former is far more complicated than the latter.

I understand the benefits of these designs, but my questions are:

1. How much benefit did they really offer over other regular roadwheel designs? (Compared to both small wheels of, say, the IS-2, and the large wheels of the T-34)

2. How come no one used these designs (interleaved or overlapping) after WW2? (Except the French, but that might've been more them directly copying Tiger 2's running gear to save time more than anything else) This suggests that the costs were considered to out-weight the benefits by all other tank-developing countries - so what made the Germans think differently?

3. Someone claimed on a forum that the design came about not because there were any benefits, but because of some industrial limitation making Germany unable to build stronger roadwheels, forcing them to use many rather than a few. Is this true?

And about the overlapping design: does this simplified still version offer any notable benefits to cross-country performance compared to placing the wheels in a single row?

I understand the benefits of these designs, but my questions are:

1. How much benefit did they really offer over other regular roadwheel designs? (Compared to both small wheels of, say, the IS-2, and the large wheels of the T-34)

2. How come no one used these designs (interleaved or overlapping) after WW2? (Except the French, but that might've been more them directly copying Tiger 2's running gear to save time more than anything else) This suggests that the costs were considered to out-weight the benefits by all other tank-developing countries - so what made the Germans think differently?

3. Someone claimed on a forum that the design came about not because there were any benefits, but because of some industrial limitation making Germany unable to build stronger roadwheels, forcing them to use many rather than a few. Is this true?

And about the overlapping design: does this simplified still version offer any notable benefits to cross-country performance compared to placing the wheels in a single row?

-

Woody Wetter

- Member

- Posts: 19

- Joined: 02 Apr 2020, 06:38

- Location: Estonia

Re: The benefits of interleaved & overlapping road wheels?

My personal opinion - because i havent found a official writing about some kind of conclusion what states why Germans used overlapping design.There are only lots of hints and conflicting information.

Many general ideas/design philosophy behind Panther , Tiger and Tiger 2 were actually from late 30s. Im talking about tanks general layout and not components(gun , engine ,transmission , armor thickness etc)!

During that time the tank production and development was not fully matured and there was search for new ideas and experimenting . The overlapped road wheels worked very well for half tracks. So in some ways it was true and tested design what later become used on bigger machines.

1) From German point of view there was no regular roadwheel design. You have to take account that even if Germans found out in 1944 the overlapped wheels were dead end it does not mean they thought same in 1941(for example) .

For Germans overlapping wheels solved few problems:

*With overlapping you can add more torsion bars(or any other spring type) so each bar can be softer and having longer suspension arm travel(offering better ride quality) than it would be possible with full size single row roadwheels(ie T-34) .

*Having lots of small wheels like(Panzer 4) was not a option for Panther/Tiger because Germans had problem with making rubber lined roadwheels what are durable enough. Smaller diameter for roadwheel means more stress to rubber .For example P4 roadwheel diameter is 470mm and outside length is 1475mm but Panther roadwheel is 860mm and outside length 2700mm. So lets say 2 fictional tanks(same weight) travel same distance then P4 roadwheels will make about twice the rotations and wear/tear than Panther larger ones. If everything else is equal then lifetime of P4 roadwheel is twice shorter.

*Also track with bigger diameter roadwheels rolls more easily over rocks , debris , logs etc.

*Stuff what gets between track and roadwheel will less likely damage rubber if roadwheel is larger.

*Another problem is the strength(n/mm2) of rubber and other material properties will be same(independent from diameter) so Germans did not had other choice to simply use maximum diameter to lessen strain. Having thicker rubber lining to accommodate extra wear(compared to larger diameter) was also problem because rubber would start to overheat(from compression) and then just melt.

It was actually problem what all nations shared and main reason was the rubber industry was not so advanced.

*When tank uses big diameter roadwheels then the wheel bearing will be also much higher from ground/water than with smaller wheel. It makes sealing of wheel bearing easier and generally adds longer lifespan.

2) Basically at the end of war 1945 it was clear to every winning nation what is the best roadwheel/return roller design for them. It came by trial and error and own experience.

There was no need for interleaved system:

*Rubber- and spring(torsion bar , coil spring etc) technology had made great progress so these components were not limiting factors at overall design.

*1945+ tanks were mainly around 40 tons so it allowed to use simpler designs to achieve good and equal ground pressure with decent components durability.

*All nations tanks designs were more universal and standard so cost cutting became very important. The times of limited productions and special projects were gone.

*Most tanks(by models and not by production number) after war went with return rollers design due having greater speed. That meant roadwheels cant be very large so there must be more of them what meant more equal weight distribution anyway.

3) For Germans the interleaved roadwheels were mix on many things why they chose that.

*Most important was issue they had to invent everything. There were no examples available how to build high speed and mobile tank what weighted 45-57 tons. Technical solutions from 20ton tanks cannot be used by just scaling them up and even in that weight range it was not clear what is best solution.

*After the Barbarossa bogged down then Germans needed quick solutions so there was no time to search for ideal design. So they got bit stuck with design what had some drawbacks but it was at least ready for production .

*Overall Germans tried to achieve best suspension by terms of smoothness and equal weight distribution and suspension travel - at the beginning of 40s only design(also bottlenecks were rubber and spring technologies) what could offer that was interleaved design. Years later other designs could offer comparable performance without downsides(complex , costly , difficult maintenance ) .

Taking account all the good and bad then after war everybody came to conclusion it is not worth it. That does not mean it was bad system and failure - just pure economy and timeline.

Many general ideas/design philosophy behind Panther , Tiger and Tiger 2 were actually from late 30s. Im talking about tanks general layout and not components(gun , engine ,transmission , armor thickness etc)!

During that time the tank production and development was not fully matured and there was search for new ideas and experimenting . The overlapped road wheels worked very well for half tracks. So in some ways it was true and tested design what later become used on bigger machines.

1) From German point of view there was no regular roadwheel design. You have to take account that even if Germans found out in 1944 the overlapped wheels were dead end it does not mean they thought same in 1941(for example) .

For Germans overlapping wheels solved few problems:

*With overlapping you can add more torsion bars(or any other spring type) so each bar can be softer and having longer suspension arm travel(offering better ride quality) than it would be possible with full size single row roadwheels(ie T-34) .

*Having lots of small wheels like(Panzer 4) was not a option for Panther/Tiger because Germans had problem with making rubber lined roadwheels what are durable enough. Smaller diameter for roadwheel means more stress to rubber .For example P4 roadwheel diameter is 470mm and outside length is 1475mm but Panther roadwheel is 860mm and outside length 2700mm. So lets say 2 fictional tanks(same weight) travel same distance then P4 roadwheels will make about twice the rotations and wear/tear than Panther larger ones. If everything else is equal then lifetime of P4 roadwheel is twice shorter.

*Also track with bigger diameter roadwheels rolls more easily over rocks , debris , logs etc.

*Stuff what gets between track and roadwheel will less likely damage rubber if roadwheel is larger.

*Another problem is the strength(n/mm2) of rubber and other material properties will be same(independent from diameter) so Germans did not had other choice to simply use maximum diameter to lessen strain. Having thicker rubber lining to accommodate extra wear(compared to larger diameter) was also problem because rubber would start to overheat(from compression) and then just melt.

It was actually problem what all nations shared and main reason was the rubber industry was not so advanced.

*When tank uses big diameter roadwheels then the wheel bearing will be also much higher from ground/water than with smaller wheel. It makes sealing of wheel bearing easier and generally adds longer lifespan.

2) Basically at the end of war 1945 it was clear to every winning nation what is the best roadwheel/return roller design for them. It came by trial and error and own experience.

There was no need for interleaved system:

*Rubber- and spring(torsion bar , coil spring etc) technology had made great progress so these components were not limiting factors at overall design.

*1945+ tanks were mainly around 40 tons so it allowed to use simpler designs to achieve good and equal ground pressure with decent components durability.

*All nations tanks designs were more universal and standard so cost cutting became very important. The times of limited productions and special projects were gone.

*Most tanks(by models and not by production number) after war went with return rollers design due having greater speed. That meant roadwheels cant be very large so there must be more of them what meant more equal weight distribution anyway.

3) For Germans the interleaved roadwheels were mix on many things why they chose that.

*Most important was issue they had to invent everything. There were no examples available how to build high speed and mobile tank what weighted 45-57 tons. Technical solutions from 20ton tanks cannot be used by just scaling them up and even in that weight range it was not clear what is best solution.

*After the Barbarossa bogged down then Germans needed quick solutions so there was no time to search for ideal design. So they got bit stuck with design what had some drawbacks but it was at least ready for production .

*Overall Germans tried to achieve best suspension by terms of smoothness and equal weight distribution and suspension travel - at the beginning of 40s only design(also bottlenecks were rubber and spring technologies) what could offer that was interleaved design. Years later other designs could offer comparable performance without downsides(complex , costly , difficult maintenance ) .

Taking account all the good and bad then after war everybody came to conclusion it is not worth it. That does not mean it was bad system and failure - just pure economy and timeline.

Re: The benefits of interleaved & overlapping road wheels?

Thank you very much for that very thoroughly made and interesting reply. I appreciate that you used sources for all the information you shared and allowed whatever contradictions there are to remain.

If I ever come across a discussion of this topic elsewhere, I'll refer them to this great reply.

If I ever come across a discussion of this topic elsewhere, I'll refer them to this great reply.

-

Yoozername

- Member

- Posts: 2619

- Joined: 25 Apr 2006, 16:58

- Location: Colorado

Re: The benefits of interleaved & overlapping road wheels?

Like a search here? LOL! The Woodster seems to respond to you....

-

Yoozername

- Member

- Posts: 2619

- Joined: 25 Apr 2006, 16:58

- Location: Colorado

Re: The benefits of interleaved & overlapping road wheels?

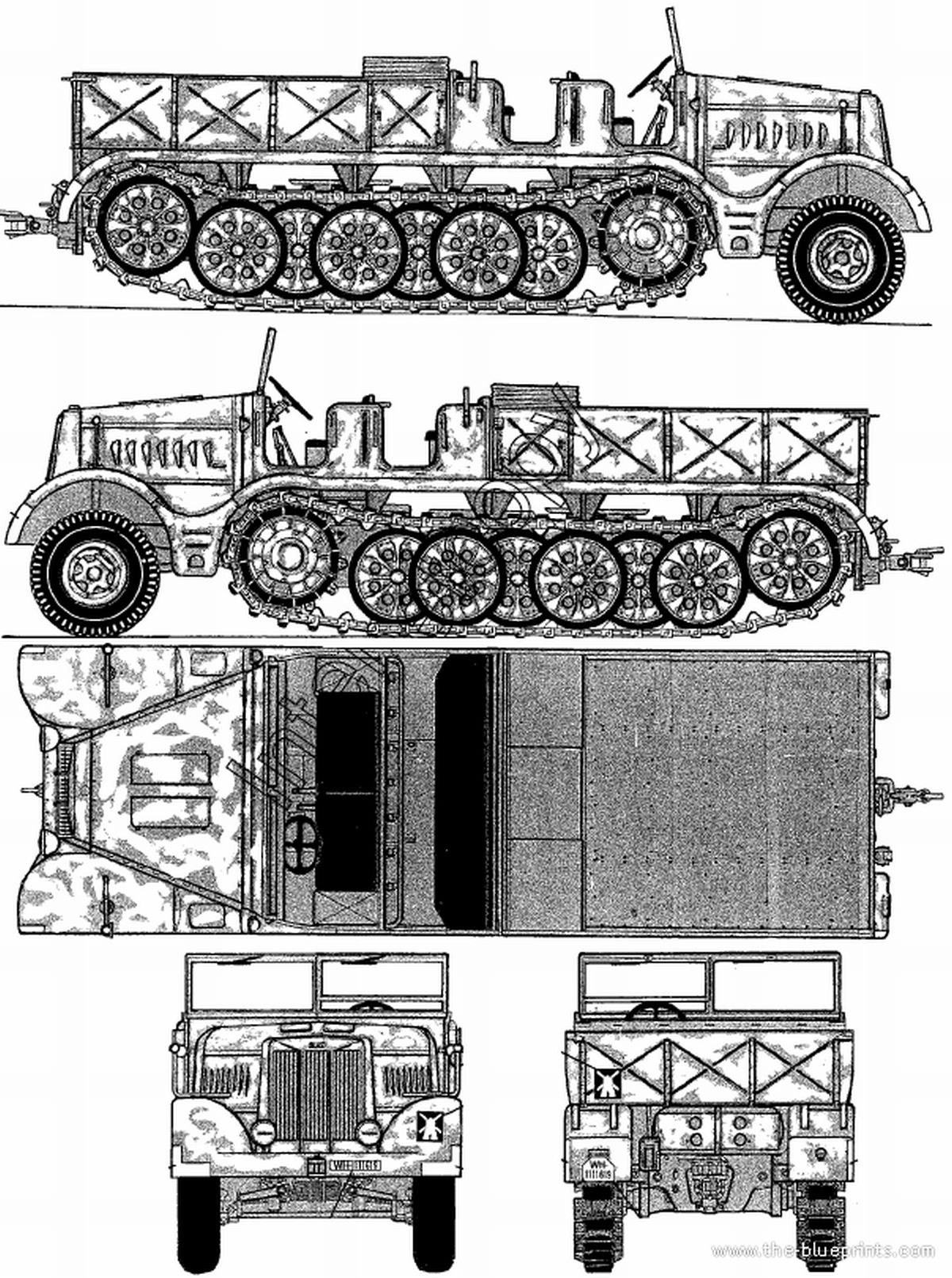

My new favorite AFV. Is it real or not?

Re: The benefits of interleaved & overlapping road wheels?

I’m guessing it’s not real...sd.kfz.8 suspension with a chafee turret?

Regarding the Panther type interleaved wheels...I recall reading an opinion in one book on the subject that said the interleaved design was used a lot by the Germans largely due to someone called Ernest Kneipkamp, who was THE senior engineer at Wa Prüf 6, the main German design office for armoured vehicles and motorized equipment under the Heereswaffenamt (Army Ordnance Department). The writer basically said that Kniepkamp just had a crush on that type of suspension, which influenced all their halftrack designs, and wanted to use it on everything else he was involved in too, like the Panther. He was a big proponent of torsion bars too. By 1944 the German designs were abandoning both those concepts. Post war, only torsion bars stood the test of time.

Regarding the Panther type interleaved wheels...I recall reading an opinion in one book on the subject that said the interleaved design was used a lot by the Germans largely due to someone called Ernest Kneipkamp, who was THE senior engineer at Wa Prüf 6, the main German design office for armoured vehicles and motorized equipment under the Heereswaffenamt (Army Ordnance Department). The writer basically said that Kniepkamp just had a crush on that type of suspension, which influenced all their halftrack designs, and wanted to use it on everything else he was involved in too, like the Panther. He was a big proponent of torsion bars too. By 1944 the German designs were abandoning both those concepts. Post war, only torsion bars stood the test of time.

-

Yoozername

- Member

- Posts: 2619

- Joined: 25 Apr 2006, 16:58

- Location: Colorado

Re: The benefits of interleaved & overlapping road wheels?

Chafee / sd.kfz.8 hybrid...Genuinely Very interesting, never heard of it before, thanks for expanding my knowledge. The article says the tracks kept falling off all the time, and it was a dud....shame, cos it looks hot!

However, i saw It also says, "The turret was removed to bring the overall weight down to approximately 32,500lb which is roughly the capacity of the suspension as used on the prime mover. Note that this means that the photograph going around the web of an M24 with the German suspension AND WITH THE TURRET is a fake, manipulated photo.

So my fake news radar was correct this time.

However, i saw It also says, "The turret was removed to bring the overall weight down to approximately 32,500lb which is roughly the capacity of the suspension as used on the prime mover. Note that this means that the photograph going around the web of an M24 with the German suspension AND WITH THE TURRET is a fake, manipulated photo.

So my fake news radar was correct this time.

Last edited by bam on 02 Feb 2021, 14:42, edited 1 time in total.

-

Woody Wetter

- Member

- Posts: 19

- Joined: 02 Apr 2020, 06:38

- Location: Estonia

Re: The benefits of interleaved & overlapping road wheels?

The German half tracks were designed not to have sharp turns. It even was not possible because steering system.

Re: The benefits of interleaved & overlapping road wheels?

From Yoozers article: turning seems to be the problem...

"All attempts to operate the vehicle in mud were futile because at every attempt to steer the track came off the idler or sprocket – usually both, and on both tracks. Presumably this is the result of the angles of departure and approach, and maybe the torsion bar positioning, as noted before the tests were started. (The yanks had to rearrange the suspension's double torsion bars. In the German HT they were placed on top of one another, but for space reasons, had to be placed side by side in the Chafee, resulting in one sides wheels & tracks being further forward than the other side, which made handling problematic)

This installation was not considered good for a study of ride characteristics because the sprocket and idler did not permit the top of the track to be level and in steering and braking the track slapped considerably. Also because of the slack track, considerable difficulty was experienced in attempting; to operate the vehicle in mud, and the tracks were thrown in every attempt to steer in mud. The rubber pads did not appear to be very durable."

...

I wonder if the German sd,kfz.8 HT had the same track throwing issues. ..I've not read of them being so, and the USA report seems to be saying the suspension was totally unusable in battle conditions, so I doubt the Germans would have used it so widely if they had found these same problems.

"All attempts to operate the vehicle in mud were futile because at every attempt to steer the track came off the idler or sprocket – usually both, and on both tracks. Presumably this is the result of the angles of departure and approach, and maybe the torsion bar positioning, as noted before the tests were started. (The yanks had to rearrange the suspension's double torsion bars. In the German HT they were placed on top of one another, but for space reasons, had to be placed side by side in the Chafee, resulting in one sides wheels & tracks being further forward than the other side, which made handling problematic)

This installation was not considered good for a study of ride characteristics because the sprocket and idler did not permit the top of the track to be level and in steering and braking the track slapped considerably. Also because of the slack track, considerable difficulty was experienced in attempting; to operate the vehicle in mud, and the tracks were thrown in every attempt to steer in mud. The rubber pads did not appear to be very durable."

...

I wonder if the German sd,kfz.8 HT had the same track throwing issues. ..I've not read of them being so, and the USA report seems to be saying the suspension was totally unusable in battle conditions, so I doubt the Germans would have used it so widely if they had found these same problems.

-

Woody Wetter

- Member

- Posts: 19

- Joined: 02 Apr 2020, 06:38

- Location: Estonia

Re: The benefits of interleaved & overlapping road wheels?

Let me repeat : The German half tracks were designed not to have sharp turns. It even was not possible because steering system.

-

Yoozername

- Member

- Posts: 2619

- Joined: 25 Apr 2006, 16:58

- Location: Colorado

Re: The benefits of interleaved & overlapping road wheels?

I agree. i recall that the steering mechanism, by turning the steering wheel not only steers the front (undriven) wheels, it varies the output to the tracks in a proportional manner. But 'drag-tracking', or completely braking one track and giving full power to the other, is really a fully tracked vehicle capability. Note the low setup of idler and drive sprocket.Woody Wetter wrote: ↑02 Feb 2021, 20:58Let me repeat : The German half tracks were designed not to have sharp turns. It even was not possible because steering system.

You would not want to run over any thing hard at high speeds. The adaption to the M24 chassis raised these items up. But the main flaw, besides the ones called out in the article, is how much distance is between the sprocket and first bogie. This combined with the slack that appears on the vehicle, combined with narrow tracks, is creating the overall slop in the system.

Compare to Luchs.

-

Woody Wetter

- Member

- Posts: 19

- Joined: 02 Apr 2020, 06:38

- Location: Estonia

Re: The benefits of interleaved & overlapping road wheels?

Half-tracks dont make sharp turns so their tracks are built with small central guides. Small guide horn means roadwheels can easily roll off. The mud and other stuff will get between track/roadwheel and lift it up so the wheels get derailed during turn.

Tanks use longer guide horns for reason.

Tanks use longer guide horns for reason.

-

Yoozername

- Member

- Posts: 2619

- Joined: 25 Apr 2006, 16:58

- Location: Colorado